From Standard to Superior

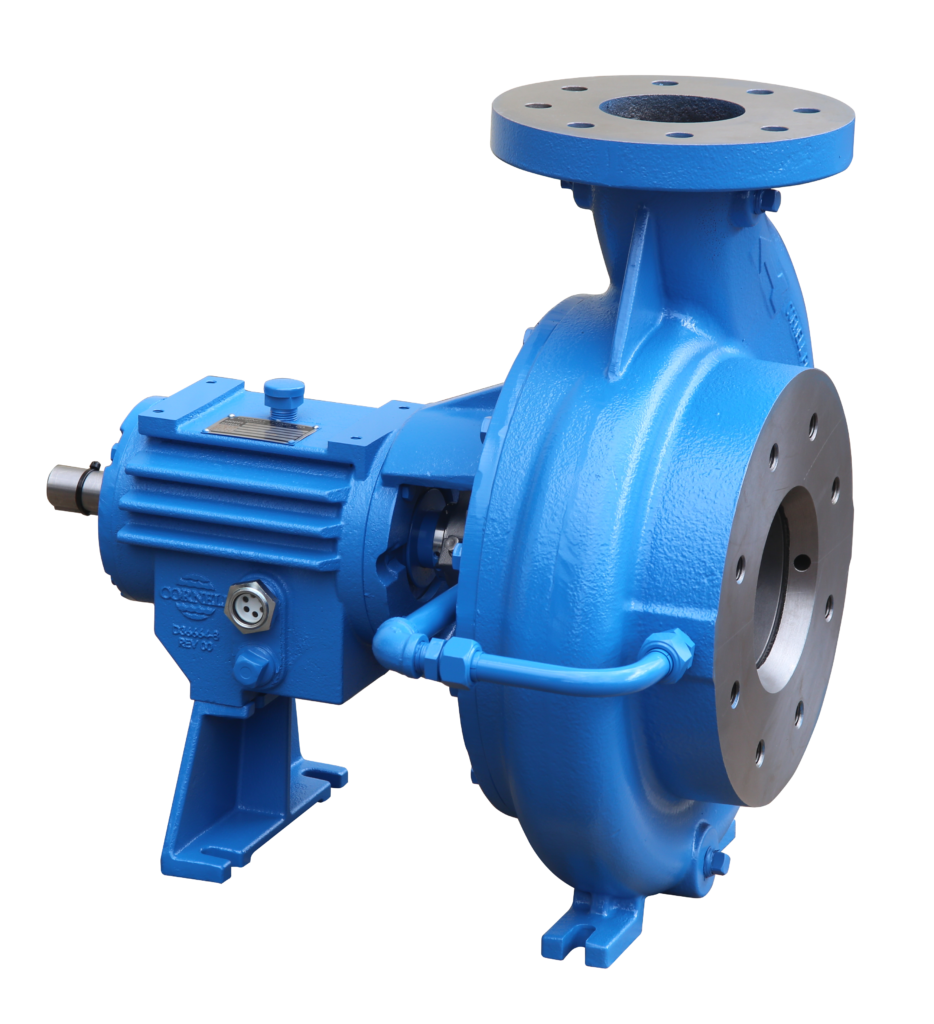

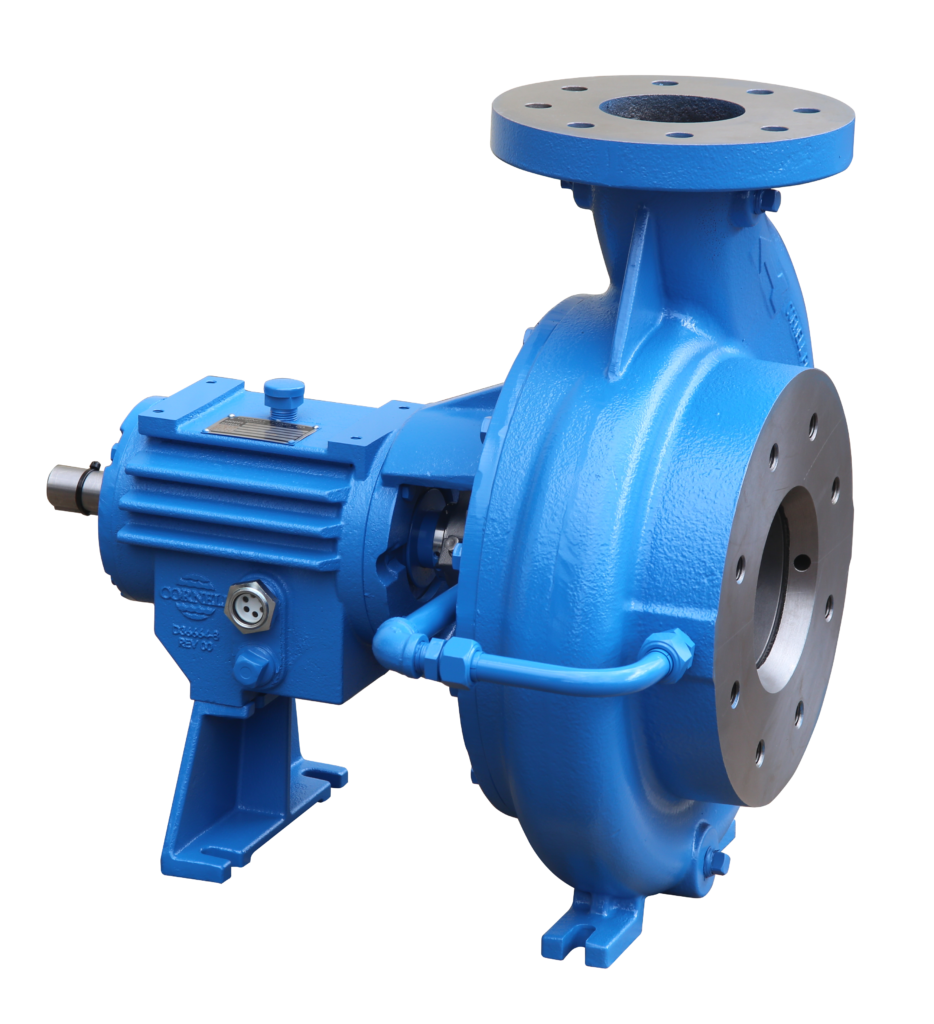

Z-Series

Pumps

We are excited to unveil the latest addition to the Cornell family: the new Z-Series of ANSI-compatible pumps! This project represents a significant milestone, offering an efficient, cost-effective, and reliable solution tailored to the dynamic demands of the single-stage end suction centrifugal market. ANSI pumps find applications across various industries, including textiles, chemicals, mining, marine, and more.

Z-Series Key Features

ANSI Compatibility

Easily placed or replaced into standard piping and base mount.

Centerline Construction

Conforms to industry standard design.

Frame Mounted, Engine Mounted or Close Coupled

Multiple mounting options to best suit users’ needs.

Ductile Iron or CD4MCU

standard design

Significantly stronger and more corrosion-resistant than many other manufacturers’ cast iron ANSI pumps, The Z-Series builds on its robust reliability from cast-on-up

Casings

Thick wall casings exceed industry standards to prolong life.

High Strength Shaft

Cornell’s oversize shafts help with deflection and wear.

Cornell Co-Pilot™ pump

monitor ready

The industry-leading rotating equipment monitor is now a standard.

Enclosed impeller

Increasing efficiency with enclosed impeller.

Oversized Oil lubed bearings

Oversized bearings better dissipate heat and prolong life, while oil is standard in ASNI configurations.

Bearing frame isolators

Protects against contamination ingress and lubrication loss, helping significantly increase the longevity and reliability of Z-Series.

Type 1 Single or Cartridge Single Seals Standard

Multiple sealing options allow maximum flexibility across applications.

Redi-Prime/ RunDry™ Capable

Cornell’s patented Redi-Prime® system allows for unattended priming and re-priming. At the same time, the RunDry™ option enables the pump to survive if it were to accidentally run without liquid media in the pump for some time.

Hydraulic balance line

Cornell’s feature makes the pump look unique—but more importantly, it helps reduce axial thrust without having to drill efficiency-sapping holes in the impeller.

- ANSI Compatible

- Performance

- Models Available

Z-Series, designed by Cornell, the industry leader in efficiency and innovative design, is not just ANSI dimensionally compatible but also a reliable choice. Consider the difference between a cheap single-blade razor and a sleek multi-blade razor with refinements and features. Both may fit dimensionally in the same space, but their performance, longevity, and ease of use differ. Similarly, Z-Series ANSI pumps offer a level of reliability that sets them apart.

| Discharge Size Range | 2” To 8” |

| Max Solids Handling | 2.5” |

| Max Flow | 5,000 GPM |

| Max Head | 750’ |

| Model | Discharge | Solids Handling | Suction | Datasheet |

|---|

Industrial Process Applications

Z-series centrifugal pumps’ robust build and higher efficiencies position the series to offer better results than standard ANSI pumps. Easy access to parts and Cornell quality since 1946 make the Z-Series an easy choice for these industries:

Municipal Purposes

Cornell has been involved in municipal applications since designing hydro turbines for Northwest electrification projects in the early 1950s. Our design knowledge and application expertise make the Z-Series uniquely suited to tackle water and wastewater applications such as:

*NSF certification forthcoming

Cornell Pump - Decades of Progress

Cornell Pump has been designing and manufacturing pumps near Portland, Oregon, since 1946. We’re a trusted manufacturer of durable and high-efficiency pumps, delivering unparalleled value to our customers. Our Z-Series pumps are engineered to meet the demanding requirements of industrial, municipal, mining, and other applications, providing unparalleled reliability, compatibility, and interchangeability. With a broad range of pump models and configurations, we can easily integrate our pumps into your existing systems. Moreover, we support custom system designs to meet your specific needs. Our team of technical and engineering experts is among the best in the industry and can provide innovative pump solutions of the highest quality.