Solids Handling Pumps

Cornell offers a broad range of pumps designed to handle challenging solids applications, with discharge sizes ranging from 1.25″ to 30″. These pumps are commonly used in the Municipal, Agricultural, and Industrial markets and can be mounted in several configurations, including close-coupled, SAE engine, horizontal, and vertical. With enclosed, semi-open, and delta impellers, and a variety of construction materials, Cornell solids handling pumps can achieve flow rates up to 40,000 GPM.

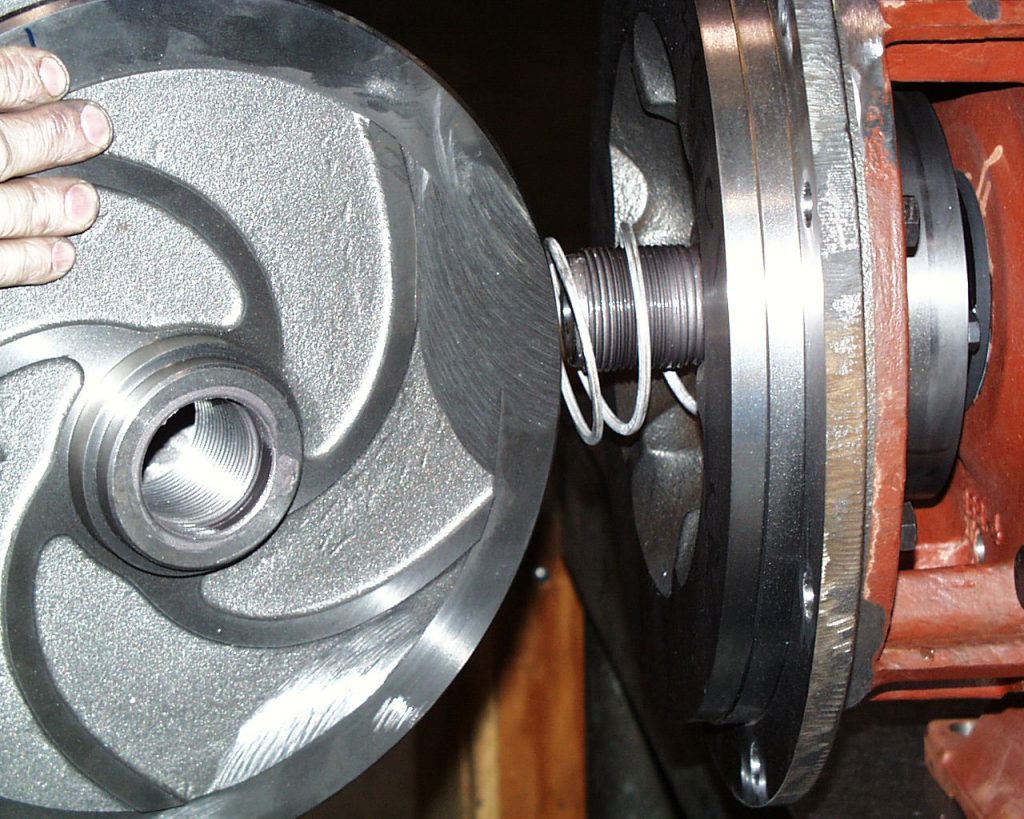

All Cornell solids handling pumps come equipped with the heavy-duty bearing frame that is easily recognizable by its angular, muscular appearance, and is a hallmark of high-quality Cornell pumps.

N-Series Solids Handling Pumps

- About

- Models Available

Cornell's N-series pumps are made to tackle challenging solids handling applications, with discharge sizes ranging from 1.25" to 30". These pumps are adaptable to various mounting options, including close-coupled, SAE engine-mount, horizontal frame-mount, and vertical coupled. They have enclosed impellers capable of handling up to 10" solids and 40,000 GPM flow, but also offer the option of a delta impeller for dealing with stringy materials and rags. The N-series has been trusted in wastewater handling for over 30 years, thanks to its sturdy and reliable design.

| Model | Discharge | Solids Handling | Suction | Datasheet |

|---|

Duraprime Series

- About

- Models Available

Cornell Pump's Duraprime® pumps are perfect for construction and rental applications and are available in 3", 4", and 6" models. These pumps are built to last, with a durable design and efficient operation. The Duraprime series comes with the Cycloseal® sealing system and Venturi Prime priming system, making it easy to operate and maintain. The Duraprime® series is known for its low operating costs and high efficiency, with a rating of up to 82%. It is also easy to service, with a rebuildable pump design and no need for seal venting or flushing. Cornell offers a two-year warranty on Duraprime® pumps.

| Model | Discharge | Solids Handling | Suction | Datasheet |

|---|

Hydro-Transport Pumps

- About

- Models Available

Nearly 50 years ago, Cornell was the first to introduce Hydro-Transport food process pumps to the industry. Unlike other pumps sometimes used in the food industry, Cornell P and PP series pumps are specifically designed and manufactured for pumping food products. They are ideal for agricultural applications such as fruit washing and packing and food manufacturing operations. Thanks to Cornell's offset spiral design, these pumps have the lowest product damage rates in the industry and are favored by food processors worldwide.

Cornell's recognizable pump frame design incorporates mounting surfaces instead of mounting feet, which can be helpful and space-saving in food plant mountings. A quality Cornell Pump frame supports the robust Cornell pump.

| Model | Discharge | Solids Handling | Suction | Datasheet |

|---|

Chopper Pumps

- About

- Models Available

Cornell's Chopper Pump is designed to handle severe plugging. The standard casing, made of ASTM A536 grade 65-45-12 ductile iron, stands up to robust applications. Everything about the pump is built to tackle complex jobs, from the replaceable cutter bar made of T1 tool steel heat treated to a minimum of 60 Rockwell C hardness to the heat-treated cast steel impeller. The Cornell Chopper pump series is a heavy-duty performer.

Cornell's recognizable pump frame design incorporates mounting surfaces instead of mounting feet, which can be helpful and space-saving in food plant mountings. A quality Cornell Pump frame supports the robust Cornell pump.

| Model | Discharge | Solids Handling | Suction | Datasheet |

|---|

CD4MCu Pumps

- About

- Features & Benefits

- Models Available

CD4MCu is a type of stainless steel that offers more excellent corrosion resistance than 316 stainless steel and has double the yield strength. Unlike common grades of single-phase stainless steel, CD4MCu is duplex stainless steel, providing the strength and hardness of 400 series stainless steel with the corrosion resistance of 300 series stainless steel. This makes it ideal for more abrasive applications and provides better corrosive cracking and pitting resistance.

- Corrosion and pitting resistance

- Higher strength than standard grades of stainless steel

- Improved ductility and weldability

- Better resistance to embrittlement

| Model | Discharge | Solids Handling | Suction | Datasheet |

|---|

Related Literature

| Image | Title | Categories | Tags | Link | hf:doc_categories | hf:doc_tags |

|---|