Cutter Pumps

Cornell’s cutters are designed to prevent ragging and plugging. The Blade Cutter minimizes efficiency loss, while the Waste Warrior tackles aggressive plugging. Installing these cutters can significantly increase pump uptime and save thousands of dollars annually. Cornell offers cutter assembly installation for over 30 pump models. The sturdy Cornell Pump frame features mounting surfaces rather than feet for added durability.

- About

- Features & Benefits

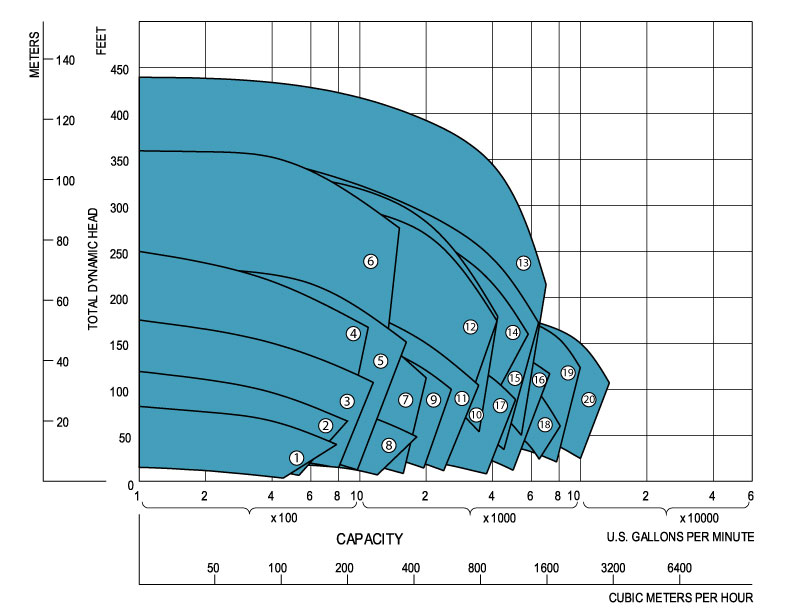

- Models Available

Cornell created their cutter pump solutions to solve clogging caused by materials like wipes and cleaning products, which can lead to pump damage, downtime, and pipe damage. Cornell's cutter pumps are helpful in various markets and use a unique blade design that allows materials to pass through the impeller without clogging. These pumps come in two versions: the Blade Cutter and the Waste Warrior.

- Designed to break up clogs and prevent ragging

- Hardened for long life

- Shaped to minimize flow restrictions

- It saves labor and downtime required to clean out clogs

- Breaks up “flushable” wipes and other materials in municipal applications

- Breaks up clumps of straw in manure applications

| Model | Discharge | Solids Handling | Suction | Datasheet |

|---|

Related Literature

| Image | Title | Categories | Tags | Link | hf:doc_categories | hf:doc_tags |

|---|