Z-Series

Z-series centrifugal pumps’ robust build and higher efficiencies position the series to offer better results than standard ANSI pumps. Easy access to parts and Cornell quality since 1946 make the Z-Series an easy choice for many industrial and municipal applications.

IoT Ecosystem

IoT Ecosystem Cornell Pump Company’s IoT ecosystem is a testament to our unwavering commitment to innovation and customer-centric efficiency improvements. We have seamlessly integrated cutting-edge IoT technologies into our pump systems, creating an interconnected network that redefines how our customers approach pump management. This ecosystem empowers our customers with real-time data insights, predictive maintenance capabilities, […]

New Hydraulic Submersible Manure Pumps

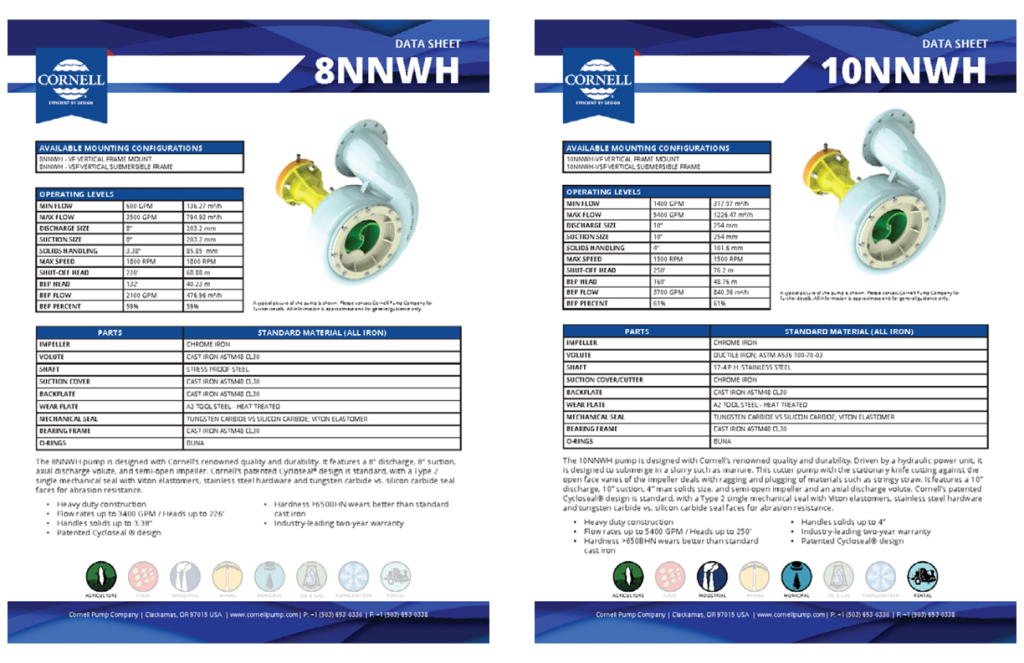

Cornell featured the new NNWH series of submersible cutter pumps at Manure Expo last week. If you didn’t get a chance to check out the pumps at the show, check out the 8NNWH and 10NNWH data sheets. The series’ features include: 8” and 10” discharge sizes Hydraulically driven Operates in lagoon or pit Fits into […]

Cornell Pump: Helping Irrigate California’s Central Valley

While California may be getting lot of winter rain currently, it is always good to plan for irrigation later in the growing season. Shown is typical pump station in California’s Central Valley. A Cornell 4RB-25 pump is on the system, producing flow of about 500 gallons per minute. This system can irrigate with either well […]

Resources

Resources Literature Find Cornell Pump Company’s current literature, such as pump data sheets, market brochures, product line brochures, application sheets, handbooks, and more. Mobile Toolkit This tool is designed to assist in making pump system selections, whether or not there is an internet connection available. Android | Apple IOS Success Stories Listen to the success […]

Cornell History

The story of Cornell starts in 1946 when 5 people working at Pacific Pump Company decided to head out on their own. Having a complete service department, they became familiar with what most of the common pump failures were. Many motor failures came from pressure spikes during operation, overloading capacity and water related failures of the pump end motor bearings. With many parts in stock and facilities to fabricate the rest, Cornell would service any model of pump.

Rental

Rental Pumps Rental pump manufacturers worldwide rely on Cornell Pump Company for high-quality, low-maintenance, and versatile pumps to include in their packages. Our pumps are used in various applications, from tar sands to flood control to construction sites. With features like Redi-Prime®, Cycloseal®, and RunDry™, our pumps are ideal for rental applications where conditions can […]

Refrigeration

Refrigeration Pumps Cornell’s industrial refrigeration pumps are purpose-built for liquid overfeed and transfer applications. With more than 35 years of experience, we are a trusted provider of high-quality, reliable pumps in the industrial refrigeration industry. Our products are designed to be tough and dependable, and we offer an industry-leading three-year warranty on every Cornell pump. […]

Oil and Gas

Oil & Gas Pumps Cornell pumps have a reputation for being durable and reliable in harsh conditions. Since 1946, our pumps have been designed and manufactured to meet rigorous standards in Portland, OR. Cornell pumps are widely used in the oil and gas industry, hydraulic fracturing, due to their exceptional uptime, dependability, and efficiency. On […]

Municipal

Municipal Pumps Cornell pumps are a reliable choice for municipal applications such as clear water, wastewater, and grey water. Cornell has provided pumps for municipal installations for over 70 years, offering permanent and temporary/emergency solutions. The new cutter pump effectively reduces waste water ragging, leading to excellent uptime and reduced maintenance costs. With a double […]