- Greater efficiency

- Grit removal

- Enhanced pump component longevity

- Better wear characteristics

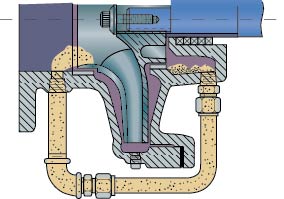

One of the key features of many Cornell clear liquid pumps, including the Z-Series, is the external hydraulic balance line. This feature enhances performance without drilling holes in impellers, which can lower efficiency by three percent or more. The Z-Series operates more efficiently by eliminating these holes, leading to significant energy cost savings.

The Z-Series pump allows high-pressure liquid from the volute to pass through the hub ring clearances into the cavity between the stuffing box and the impeller. The liquid then returns via the balance line to the lower pressure region at the pump inlet, carrying with it any sand or silt that could build up at the stuffing box. This method reduces turbulence, improves hydraulic efficiency, increases the life of packing, mechanical seals, and bearings, and provides positive control of axial forces. It also reduces wear because sand is not trapped behind the impeller near the shaft.

While the Z-Series has only been out for a few weeks, many of Cornell’s clear liquids lines have utilized balance lines to remarkable success for decades. This proven technology makes a marked difference in pump performance.

Learn more about this exciting series, see the more than three dozen industrial, municipal, mining, and agricultural applications for this process pump, and check out individual pump specifications at our landing page: www.cornellpump.com/Z-Series