(This Tuesday Tip uses the venerable and well love Cornell Handbooks Installation & Care and Pump Seminar. If you don’t have a copy of these materials you can visit our contact page to request: https://www.cornellpump.com/contact/)

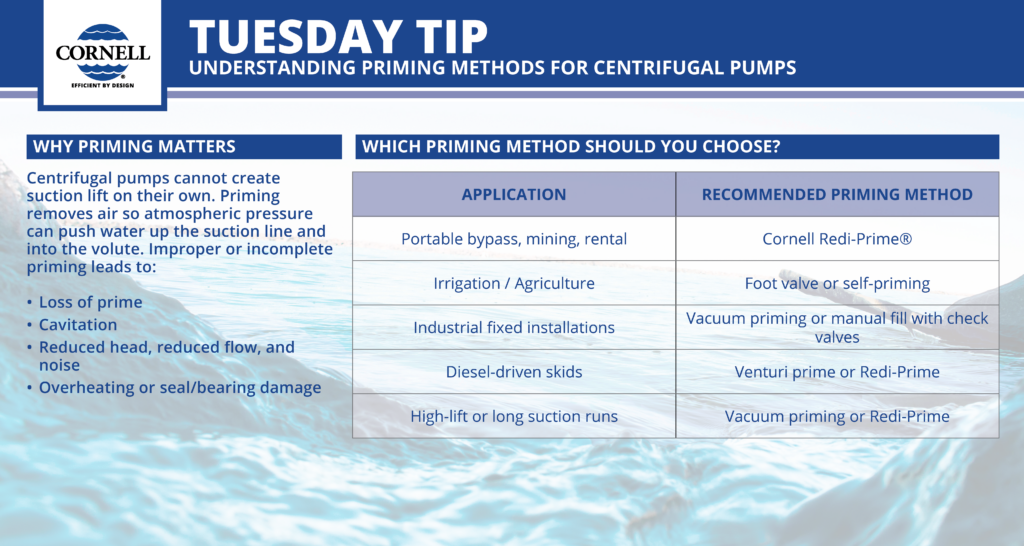

Why Priming Matters

Centrifugal pumps cannot create suction lift on their own. Priming removes air so atmospheric pressure can push water up the suction line and into the volute. Improper or incomplete priming leads to:

- Loss of prime

- Cavitation

- Reduced head, reduced flow, and noise

- Overheating or seal/bearing damage

(See cavitation and air-entrainment concerns in the Hydraulic Seminar Workbook.)

Priming Methods

1. Manual Priming (Filling the Pump & Line)

The most basic method: manually filling the casing and suction line with liquid before startup.

Advantages

- Simple and low-cost

- No additional equipment required

Disadvantages

- Labor-intensive

- Prone to operator error

- Any trapped air can prevent prime

- Not suitable for frequent start–stop or unattended operation

2. Hand Primer

A manual vacuum pump creates suction in the line to draw liquid into the volute.

Advantages

- Inexpensive

- Useful in remote or mobile installations

Disadvantages

- Requires manual operation

- Limited vacuum capability

- Not ideal for large suction lifts or long runs

3. Foot Valve Priming

A foot valve holds liquid in the suction line after filling, allowing the pump to remain primed between cycles.

Advantages

- Simple and common on agricultural and irrigation apps

- Helps maintain liquid column

Disadvantages

- Foot valves can clog, leak, or fail

- Even minor leakage allows air in, causing loss of prime

- Adds suction-line friction loss

- Requires venting air during filling

4. Self-Priming Pumps

These retain water in the casing. During operation, water recirculates, mixes with air, and ejects air from the casing until the suction line is fully primed.

Advantages

- Fast, repeatable priming

- Good for intermittent-duty systems

- No external priming device

Disadvantages

- Larger, more complex pump casing

- Lower efficiency than standard end-suction designs

- Requires liquid retention in casing—cannot be allowed to drain dry

5. Vacuum Priming Systems

An external vacuum pump draws air from the pump casing and suction line until liquid enters the volute. System shuts off automatically once prime is achieved.

Advantages

- Reliable automatic priming and re-priming

- Excellent for deep suction lifts

- Ideal for municipal, mining, and industrial applications requiring unattended duty

Disadvantages

- Additional equipment and controls

- Higher initial cost

- Requires maintenance of vacuum components

6. Venturi (Exhaust) Priming

Engine-driven pumps can use exhaust flow to create vacuum, drawing liquid into the pump.

Advantages

- No separate vacuum pump required

- Good for portable diesel-driven units

Disadvantages

- Dependent on engine exhaust conditions

- Less reliable than dedicated vacuum systems

- Not suited for low-speed or low-load conditions

7. Automatic Priming – Cornell Redi-Prime®

Cornell’s proprietary system uses:

- A positive sealing float box,

- A diaphragm vacuum pump, and

- An air/water separation chamber

to fully automate priming and re-priming without water carryover.

Advantages

- True unattended operation

- Handles air/water mixtures easily

- No water carryover into vacuum pump

- Extremely reliable for rental, bypass, mining, and wastewater applications

Disadvantages

- Higher upfront investment

- More components vs. manual systems

- Requires periodic inspection of floats and vacuum components

Priming Best Practices

Across all methods, proper system design is critical:

- Avoid air entrainment

Discharging above water surface or using poorly designed sumps introduces air that can prevent priming.

- Ensure adequate submergence

Insufficient submergence leads to vortexing and loss of prime.

- Proper suction piping

Avoid high points, sharp elbows near the pump, and concentric reducers. These trap air and promote cavitation.

- Maintain seals and packing

Air leakage at stuffing boxes or mechanical seals is a common cause of lost prime.

Which Priming Method Should You Choose?

Application | Recommended Priming Method |

|---|---|

Portable bypass, mining, rental | Cornell Redi-Prime® |

Irrigation / Agriculture | Foot valve or self-priming |

Industrial fixed installations | Vacuum priming or manual fill with check valves |

Diesel-driven skids | Venturi prime or Redi-Prime |

High-lift or long suction runs | Vacuum priming or Redi-Prime |