Pumpline Blog

Stay up-to-date with the latest from Cornell.

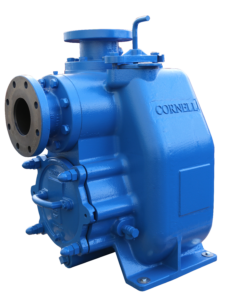

Cornell STX Self-Priming Pumps—Truly Efficient by Design

When selecting a self-priming pump, it’s easy to focus on...

Read MoreSizing a Pump for Drip Irrigation: A Practical Guide from the Field

By Ryan Hergenroder, Regional Manager – Southwest Agriculture, Cornell Pump...

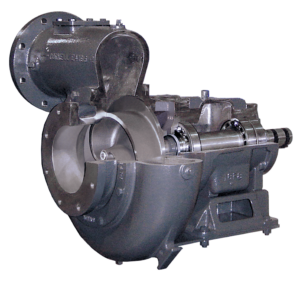

Read MoreUnderstanding Shaft Deflection—and How It Affects Mining Pumps

In high-demand pumping environments like mining, reliability is non-negotiable. One...

Read MoreDelta™ Impellers Deliver Superior Solids Handling for Municipal Wastewater Systems

Municipal wastewater operators face an ongoing challenge: how to reliably...

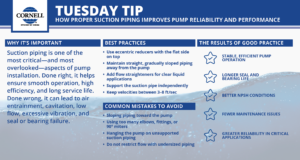

Read MoreTuesday Tip: How Proper Suction Piping Improves Pump Reliability and Performance

Suction piping is one of the most critical—and most overlooked—aspects...

Read MoreHow Cornell Rental Pumps Helped Reclaim a Contaminated Creek

When a serious PCB contamination was discovered in a creek...

Read MoreCornell’s 3PL Baytown TX Warehouse is Stocked, Staffed, and Ready to Deliver

To better serve our growing customer base—especially in the rental...

Read MoreHow Memphis is Advancing Wastewater Compliance with Co-Pilot™ SCADA

To protect water quality and meet the growing demand for...

Read MoreCornell EZ Prime Electric Vacuum-Assisted Priming System

The Cornell EZ Prime is a compact, 12VDC electric-driven vacuum...

Read MoreKEEP UP WITH THE LATEST NEWS

Subscribe today to keep up with all of Cornell Pump's news.