Cutters vs. Choppers: Choosing the Right Impeller for Modern Wastewater Challenges

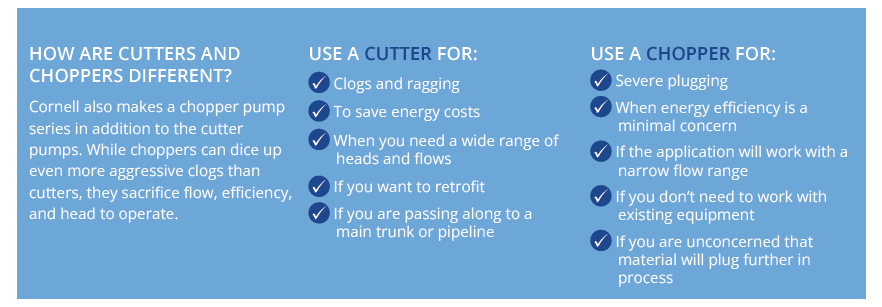

Both impeller types are designed to reduce the size of solids before they reach the pump volute, but they differ in approach, efficiency, and ideal use cases.

Cutter Impellers: Efficient Shearing at the Inlet

Cutter pumps use a rotating impeller with integrated cutting surfaces that work against a fixed cutter ring at the suction inlet. This shearing action slices fibrous materials—such as wipes, rags, and hair—as they enter the pump, reducing ragging and clogging.

Advantages of Cutter Pumps

- Lower NPSHr: Minimal restriction at the suction improves net positive suction head required.

- Higher Hydraulic Efficiency: Cutter pumps generally maintain better efficiency than chopper designs.

- Retrofit-Friendly: Easily adapted to existing pump stations without significant system redesign.

- Versatile Flow Ranges: Suitable for a broad range of operating conditions.

- Upgradable Designs: Multiple generations of cutter impellers are available, including models with integrated augers for added cutting action.

Limitations

- Less effective on hard or bulky solids (e.g., plastics, bones).

- Some reduction in efficiency compared to traditional solids-handling impellers, though often negligible given maintenance savings.

Use a cutter impeller when:

- Solids are primarily fibrous (wipes, rags, stringy materials).

- Energy efficiency and reduced maintenance are key priorities.

- Retrofits or drop-in replacements are needed in legacy stations.

Chopper Impellers: Aggressive Solids Management

Chopper pumps feature external rotating blades and fixed cutting bars located near the pump suction. These elements break down tougher solids before they enter the impeller eye, allowing even dense or irregular materials to pass through.

Advantages of Chopper Pumps

- Superior Solids Handling: Ideal for dense, hard, or compacted materials.

- High-Torque Cutting: Excels in aggressive applications with heavy debris.

- Ragging Resistance: Excellent performance in challenging wastewater or industrial flows.

Limitations

- Higher NPSHr: The external cutter assembly creates suction-side obstruction.

- Lower Efficiency: Hydraulic performance is reduced compared to cutter pumps.

- Limited Flow/Head Range: Best suited for systems specifically designed for chopper functionality.

Use a chopper impeller when:

- Solids include hard trash like plastics, bones, or dense agricultural waste.

- Plugging risk is high and aggressive solids reduction is required.

- New system installations can accommodate increased suction requirements.

System Design Considerations

Selecting between a cutter or chopper impeller involves evaluating more than just pump curves or efficiency specs. End users must consider:

- Solids composition (fibrous vs. hard solids)

- Retrofit vs. new system

- Net Positive Suction Head Available (NPSHa)

- Maintenance frequency and associated labor costs

- System flow variability and nighttime low-demand scenarios

Often, the total cost of ownership—including maintenance labor, downtime, and pump cleanout frequency—makes a slightly less efficient cutter or chopper pump more economical than a high-efficiency non-clog that clogs weekly.

Final Word: Reliability Matters More Than Efficiency Alone

While energy savings are important, unplanned downtime and frequent ragging cleanouts can far outweigh marginal gains in efficiency. Cutter and chopper pumps offer targeted solutions to drastically reduce clogging, maintenance, and operational interruptions.

Cornell Pump provides field-proven designs in both cutter and chopper configurations. Our latest cutter impellers, featuring expanded cutting surfaces and hardened components, are eliminating thousands in annual maintenance costs across municipal, industrial, and agricultural installations.

Learn more about our municipal pump offerings

Contact our application specialists for tailored recommendations.

Cutter vs. Chopper Pump Comparison

| Category | Cutter Pump | Chopper Pump |

|---|---|---|

| Used For | Clogs and ragging | Severe plugging |

| Typical Energy Efficiency Range | 85% to 65% | 65% to 45% |

| Head and Flow Range | Wide | Moderate |

| Retrofittable to Existing Pumps | Yes | No |

| Greatest Strength | Energy efficiency; better solids handling than standard pumps | Handles moderate to severe plugging aggressively |

| Greatest Challenge | Long rag ropes, fats, oils, and grease can reduce performance | Less operating range; risk of material recombination |