Introducing the FlexiBase™: Faster Installs, Smarter Support for Agricultural Pumps

When it comes to agricultural pumping systems, speed and ease count—whether you’re installing, servicing, or aligning equipment in the field. That’s why Cornell Pump has introduced a smart new solution: the FlexiBase™ adjustable pump base, designed to simplify installations, enhance stability, and improve overall pump performance.

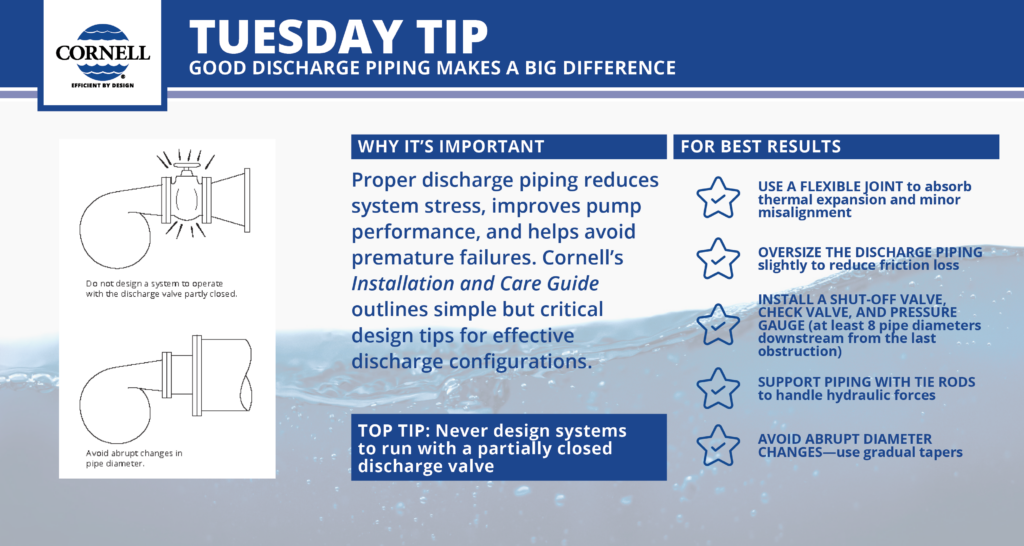

Tuesday Tip: Good Discharge Piping Makes a Big Difference

Recently, we shared best practices for suction piping. This week, we’re focusing on the other side of the pump—discharge piping.

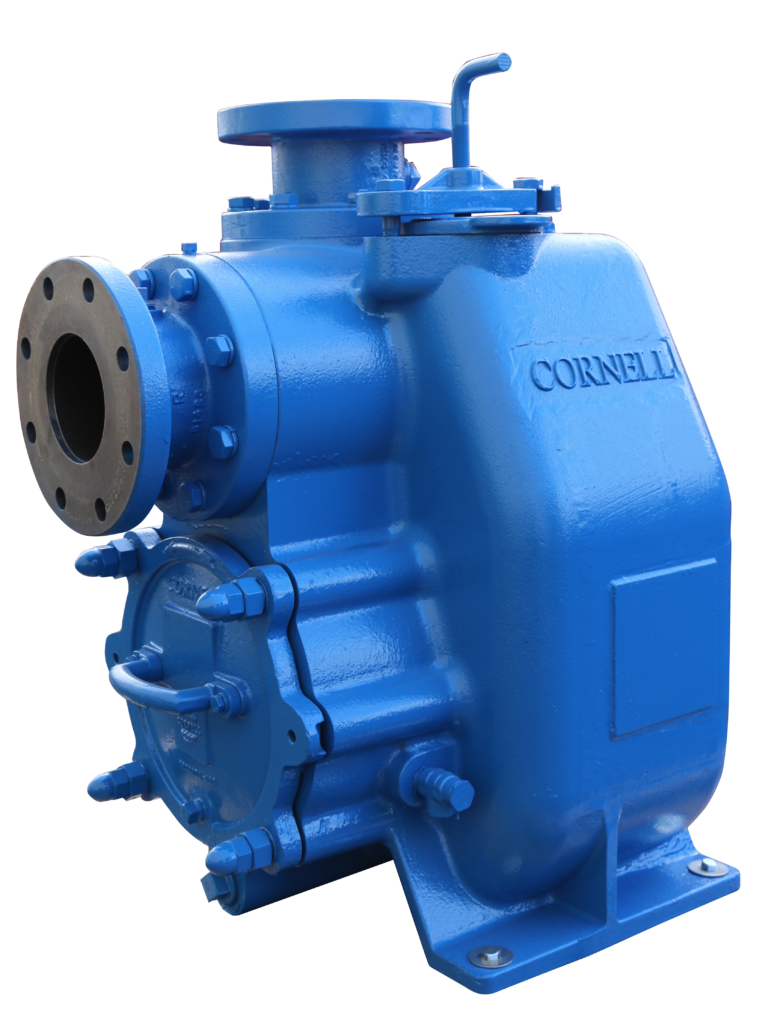

Cornell STX Self-Priming Pumps—Truly Efficient by Design

When selecting a self-priming pump, it’s easy to focus on specs like flow and lift. But in real-world applications, efficiency is what drives long-term success. Cornell’s STX-Series pumps are engineered to deliver not just performance—but highly efficient, reliable operation that reduces costs and downtime over the life of the pump.

Sizing a Pump for Drip Irrigation: A Practical Guide from the Field

By Ryan Hergenroder, Regional Manager – Southwest Agriculture, Cornell Pump Company

When I’m helping a grower size a pump for a drip irrigation system, we always start with the basics—but the conversation usually goes a lot deeper than just picking a pump off the shelf.

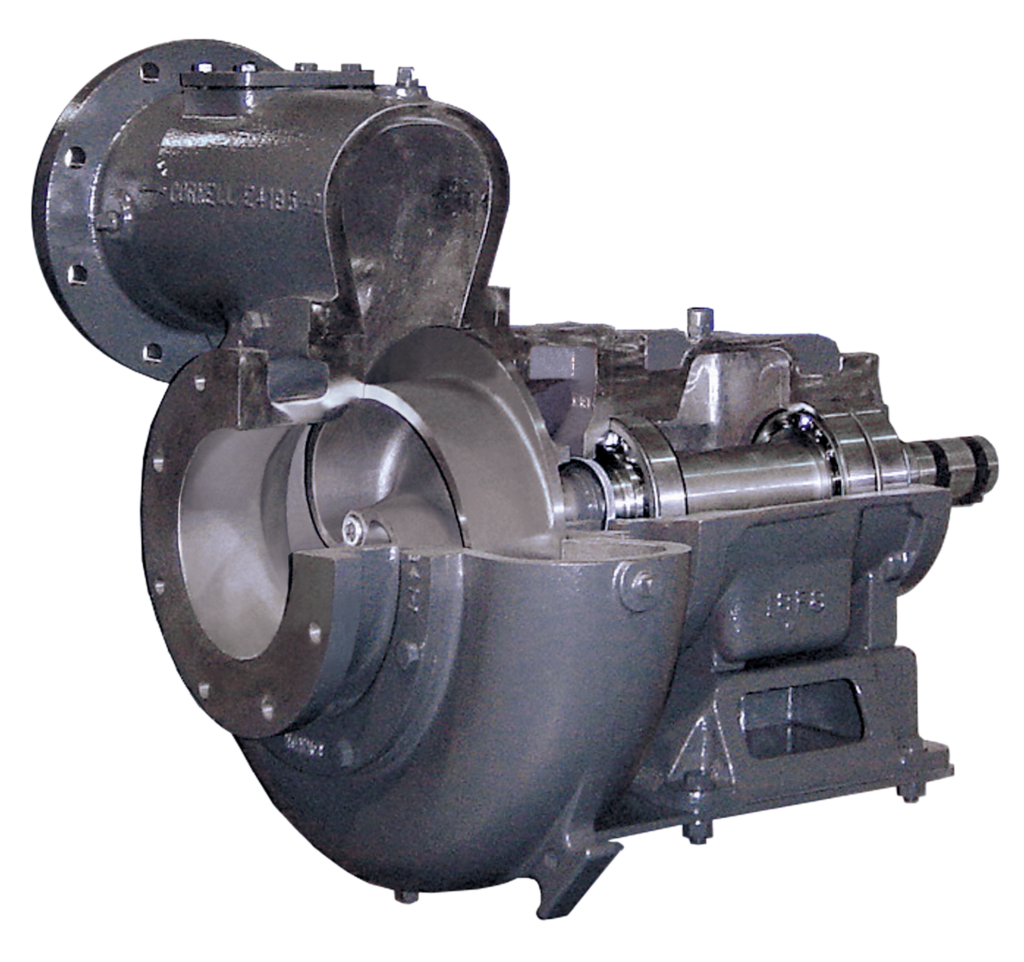

Understanding Shaft Deflection—and How It Affects Mining Pumps

In high-demand pumping environments like mining, reliability is non-negotiable. One of the less visible but critical factors affecting pump life and performance is shaft deflection.

Delta™ Impellers Deliver Superior Solids Handling for Municipal Wastewater Systems

Municipal wastewater operators face an ongoing challenge: how to reliably move liquids filled with solids, rags, and fibrous debris—without clogging, reduced efficiency, or constant maintenance. That’s where Cornell’s Delta™ Impeller technology stands out.

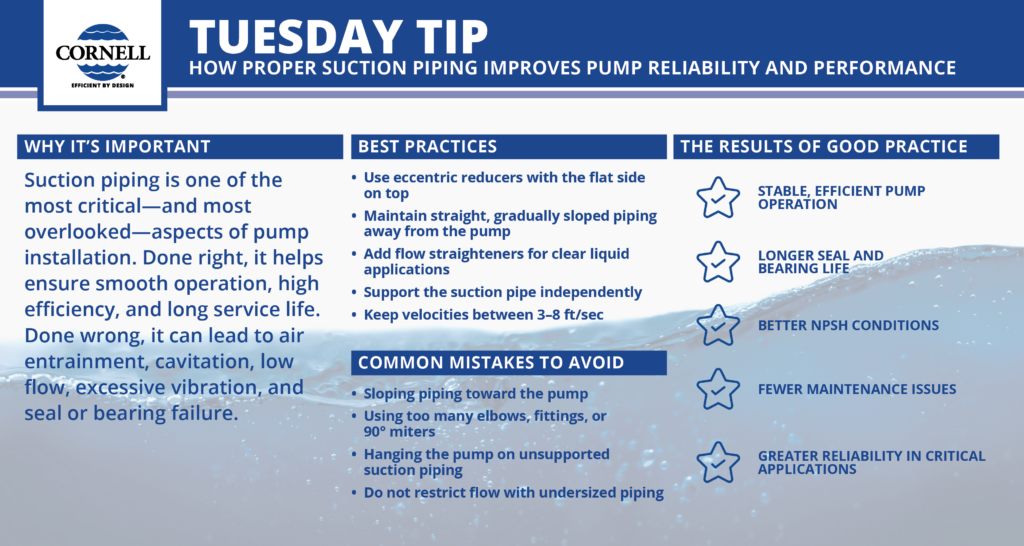

Tuesday Tip: How Proper Suction Piping Improves Pump Reliability and Performance

Suction piping is one of the most critical—and most overlooked—aspects of pump installation. Done right, it helps ensure smooth operation, high efficiency, and long service life. Done wrong, it can lead to air entrainment, cavitation, low flow, excessive vibration, and seal or bearing failure.

How Cornell Rental Pumps Helped Reclaim a Contaminated Creek

When a serious PCB contamination was discovered in a creek in Southwest Michigan, environmental cleanup became an urgent priority. The source—an old paper mill—had long since shut down, but the impact remained. To allow the EPA to safely remove and remediate the polluted soil, the project required a large-scale bypass system to re-route the creek, segment by segment.

Cornell’s 3PL Baytown TX Warehouse is Stocked, Staffed, and Ready to Deliver

To better serve our growing customer base—especially in the rental and industrial pump markets—Cornell Pump stocks a dedicated warehouse and logistics hub in Baytown, Texas. This new 3PL facility is strategically positioned to provide faster deliveries, enhanced product availability, and superior customer support across the Southern U.S. and beyond.

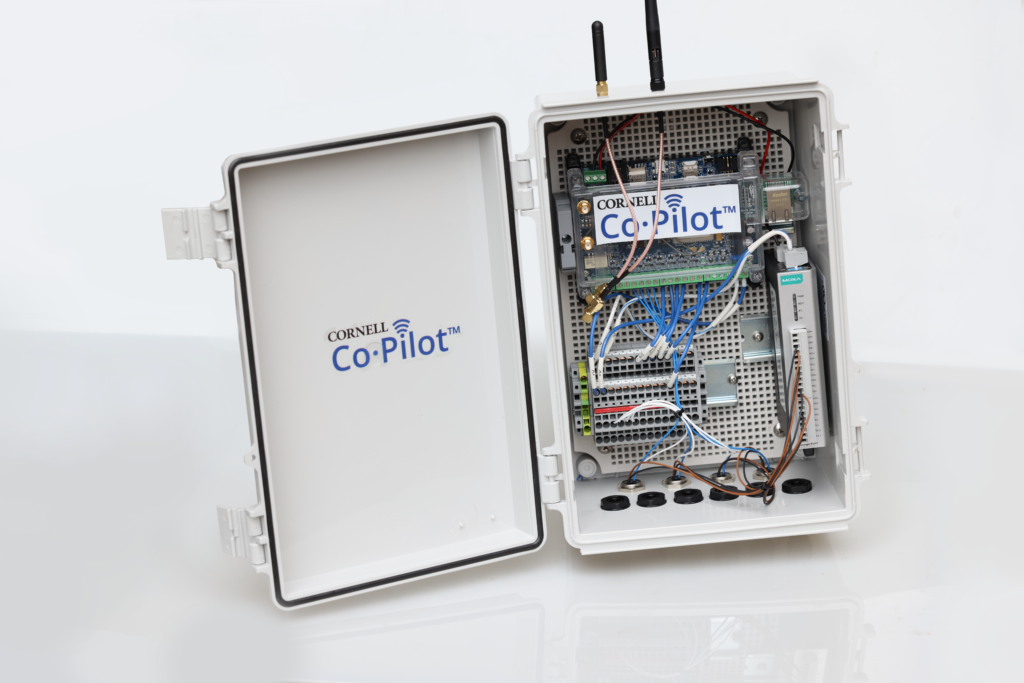

How Memphis is Advancing Wastewater Compliance with Co-Pilot™ SCADA

To protect water quality and meet the growing demand for wastewater infrastructure, the City of Memphis is taking a proactive approach to water management. A key part of that strategy includes individual businesses and organizations deploying the Cornell Co-Pilot™ SCADA Lift Station system—a powerful, cost-effective tool for real-time monitoring, reporting, compliance, and system performance, to monitor and control their pump out wells before sending into the force main.