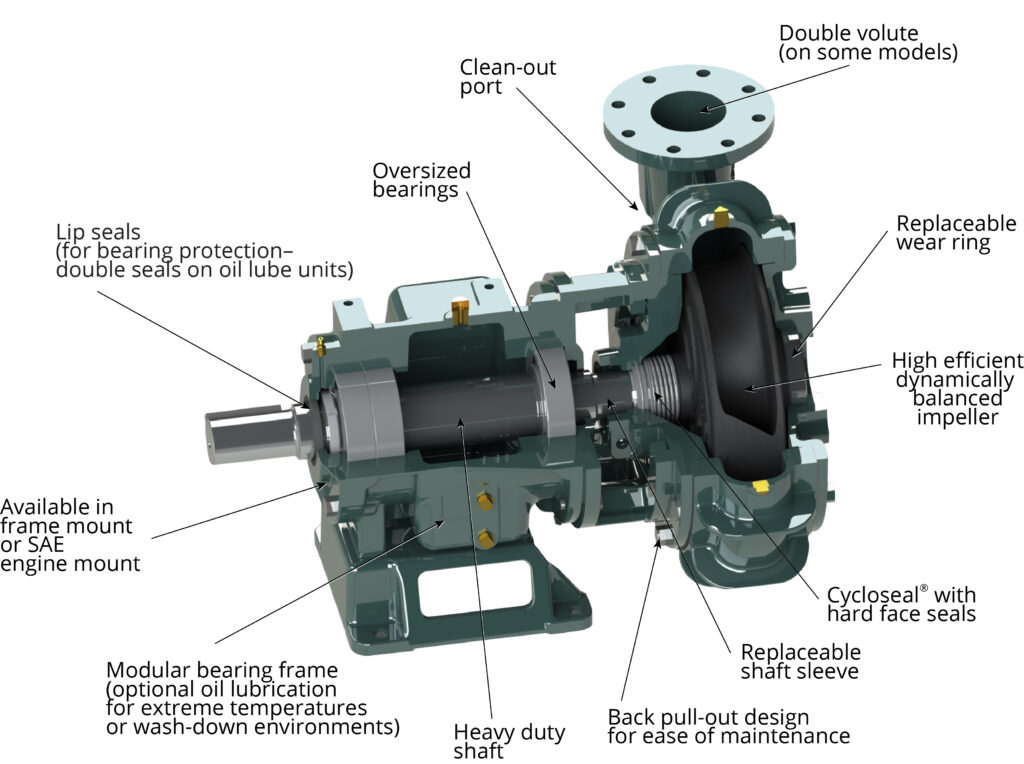

Cornell SM Series: Slurry Tough, Series Ready, Infinitely Adjustable

When handling abrasive, high-solids slurries, you need more than a standard pump — you need a workhorse built for punishing conditions. Cornell’s SM Series slurry pumps deliver unmatched performance, durability, and serviceability for demanding applications like mine tailings, sand and gravel, and other heavy-duty slurry systems.

Cornell’s Cycloseal® Pumps Prove Their Worth in Colombian Nickel Mining

Cornell Pump’s patented Cycloseal® technology is redefining pump reliability in mining. Learn how a Colombian nickel mine achieved over 9,000 hours of flawless operation, zero downtime, and massive cost savings using Cornell’s mining pumps.

N Series Pumps: Proven Solids-Handling Performance for Industrial, Mining, Rental, and Municipal Applications

For more than seventy years, Cornell Pump Company has engineered rugged, efficient, and field-proven pumping solutions. Among its most versatile product lines, the N Series stands out as a workhorse for solids-handling applications across a broad spectrum of markets—including industrial, mining, municipal, and rental sectors.

Lowering the True Cost of Ownership in Mining Pump Applications

In mining operations, the cost of ownership goes far beyond the initial purchase price. Equipment operating in remote, high-demand environments must deliver reliable performance with minimal maintenance and downtime. Cornell mining pumps, engineered specifically for abrasive and rugged conditions, offer significant advantages over competing brands when evaluating lifetime operating costs.

Engineered to Endure: Why High Chrome White Iron Excels in Abrasive Pumping Applications

In environments where abrasion is relentless—mining, manure handling, wastewater processing, and industrial slurry applications—pump failure isn’t just inconvenient; it’s costly. That’s why material choice matters, and why Cornell’s high chrome white iron construction stands out as a superior solution.

The Crucial Role of Metallurgy in Mining: Combatting Wear and Corrosion

In the world of mining, few factors impact equipment performance and lifespan more than wear and corrosion. Pumps, in particular, face a relentless barrage of abrasive slurries and chemically aggressive fluids that can prematurely degrade internal components. That’s why metallurgy isn’t just a minor detail; it’s a decisive factor in mining pump system reliability and cost of ownership.

Come Visit Us at SME

We are open at SME at booth #2300. Come by to see mining our pumps, Co-Pilot and Pulse pump monitoring systems and more. See the progression of the booth from set-up to opening.

Visit Cornell Pump at SME in Salt Lake City

Cornell Pump is exhibiting at Booth 911 at SME through March 2, 2022. Stop by and see Cornell Co-Pilot for pump monitoring, robust SM series for heavy slurry, MP series for coarse abrasives, and much more.

Seal Replacement Video

Cornell’s new instructional video explains how to replace a seal on a pump with a threaded impeller. Useful in manure, as well as some industrial and mining applications, the video can be viewed in conjunction with many of the other instructional videos on Cornell Pump’s YouTube channel. We cover a range of topics, from replacing […]

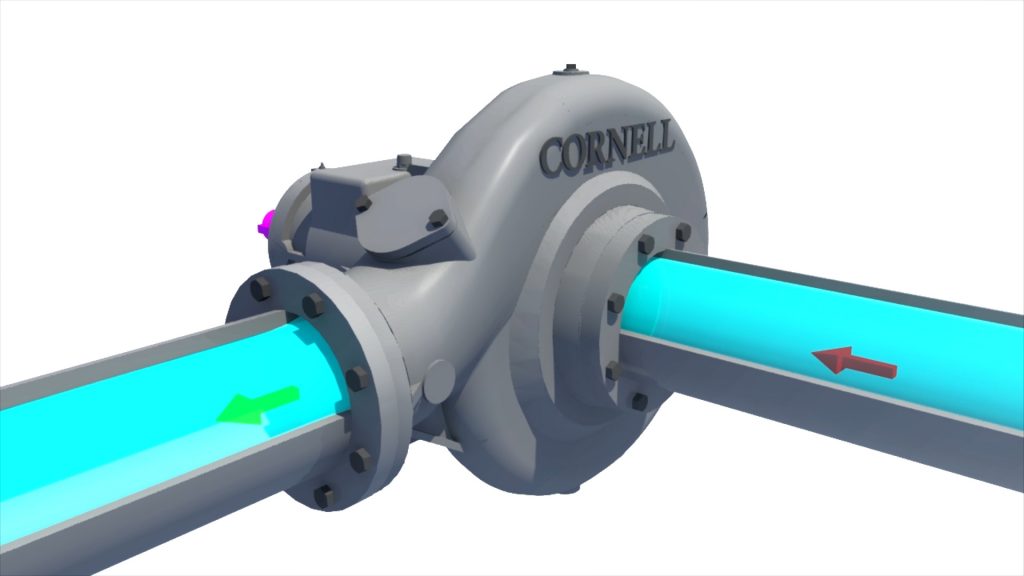

Cycloseal System

Learn about the innovative Cycloseal® System from Cornell Pump and how it extends the life of your pump seals.