What Is Minimum Submergence?

Minimum submergence is the required vertical distance between the liquid surface and the centerline of the pump’s suction inlet. This distance prevents the formation of vortices—air-entraining whirlpools that can disrupt suction, reduce head, lower flow, create noise, and diminish overall efficiency. Severe vortexing can even cause the pump to lose prime entirely.

What Happens If You Don’t Have Enough Submergence?

Operating with insufficient submergence can result in:

- Air entering the suction line, reducing performance

- Loss of prime

- Excessive noise and vibration

- Reduced flow and head

- Potential pump damage from cavitation

Factors Affecting Minimum Submergence

The correct submergence depth depends on several factors, including:

- Fluid velocity: Higher velocities require greater submergence

- Pipe diameter: Larger diameter pipes need more submergence

- Fluid properties: Surface tension, viscosity, and density can influence vortex formation

- Vortex potential: Preventing vortexes is critical to maintaining performance

Submergence Guidelines

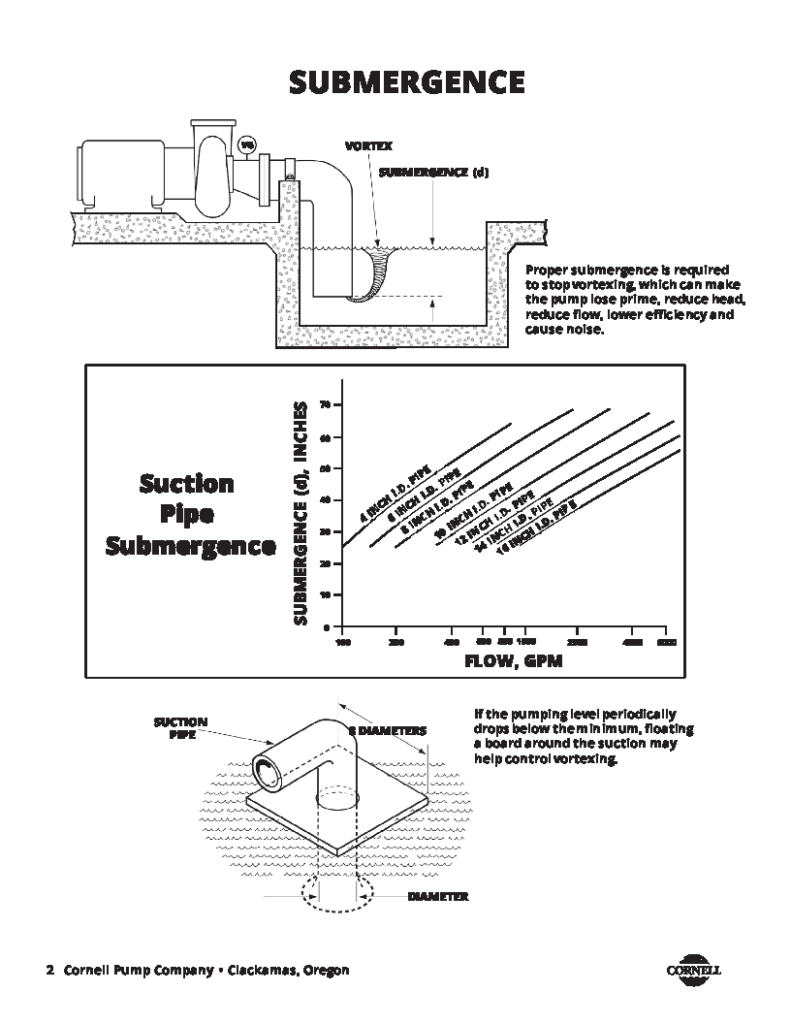

A common rule of thumb is to maintain a submergence of at least 5 times the suction pipe diameter, but this is often insufficient for many real-world applications.

For example:

- A 6-inch suction pipe at typical flow rates (such as 400 GPM) is suggested from the graphic below to have minimum submergence of about forty inches (3.33 feet) to prevent vortexing and air entrainment. That is almost 7 times the pipe diameter.

- At higher flow rates, the required submergence will increase accordingly.

If pumping levels fluctuate, a suction bell may be required to help control vortexing in marginal conditions—a tip we covered in a previous Tuesday Tip. Please refer to it for more information about suction bells.

Best Practices for Preventing Vortexing

- Reference ANSI/HI 9.8 standards for pump intake design and submergence guidelines based on flow rates and pump types

- Use vortex breakers if needed, even when recommended submergence is maintained

- Apply sound engineering judgment—consider your specific application and conditions

- For specialized situations like flumes or non-standard pumps, verify submergence requirements with your manufacturer

Why It Matters

Following minimum submergence recommendations improves reliability, extends equipment life, and ensures your pump delivers optimal performance. Ignoring it can lead to operational issues that cost time and money to correct.

For specific guidelines on your pump model, always refer to the manufacturer’s installation and care instructions.

This tip is based on Cornell Pump’s Installation & Care Workbook. For more resources, visit www.cornellpump.com.