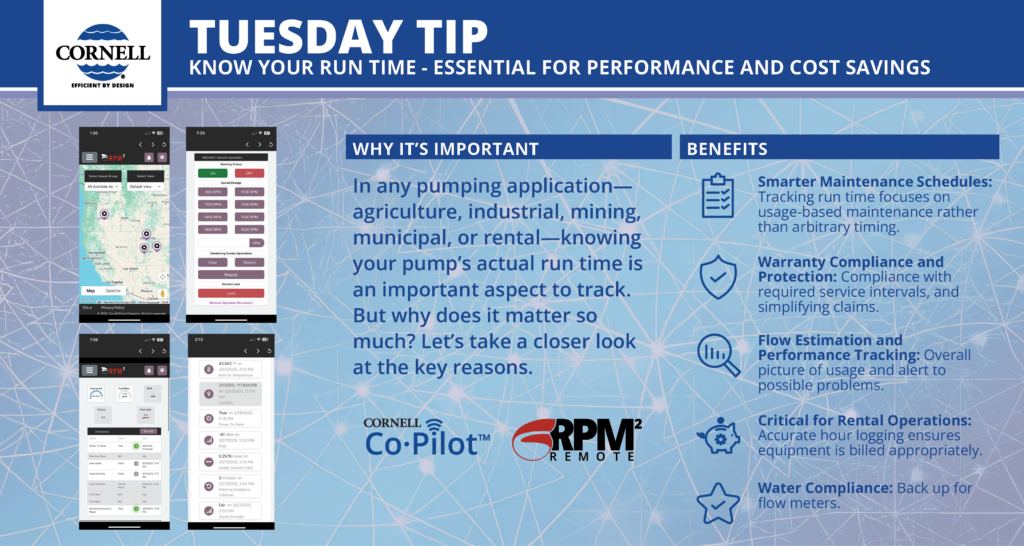

1. Smarter Maintenance Schedules

Tracking run time allows you to move away from arbitrary calendar-based maintenance to usage-based maintenance. Instead of servicing equipment “just because,” you can plan maintenance and part replacements (like seals, wear rings, and bearings) based on actual usage hours. This approach saves time and money, avoids unnecessary work, and ensures that your equipment gets the care it needs exactly when it needs it.

2. Warranty Compliance and Protection

Pump warranties may be tied to run hours. Being able to accurately track those hours helps you stay in compliance with recommended service intervals, protecting your warranty and ensuring prompt support if an issue arises. Additionally, having documented run time data can simplify warranty claims and protect you if a claim arises.

3. Critical for Rental Operations

For rental companies, tracking run time is especially vital. Accurate hour logging ensures that equipment is billed appropriately based on usage, not just rental period. It also helps identify overuse or misuse by renters, which could impact equipment health and lead to higher repair costs if left unchecked.

4. Flow Estimation and Performance Tracking

Run time can provide valuable clues for estimating flow and overall system performance. If a pump is running longer than expected to achieve a target flow or pressure, it may signal that system conditions (like clogging or wear) are changing. This early warning can help prevent bigger issues and optimize system efficiency.

5. Water Compliance

In agricultural irrigation, flow meters are the primary tool for measuring water usage, but tracking pump run time provides a valuable backup and validation. By logging how long pumps operate, farmers and irrigation managers gain a second layer of insight into overall water usage, which is especially important if flow meters malfunction or provide incomplete data. This dual approach—monitoring both flow rates and run time—ensures a comprehensive view of water usage, supports compliance with water regulations, and helps promote sustainability in farming practices.

Conclusion

If you’re not already tracking your pumps’ run time, you’re missing a key tool to improve performance, reduce costs, and protect your assets. With smart monitoring systems like Cornell Co-Pilot™ and RPM2®, it’s never been easier to capture this critical data and put it to work for your operation.

Questions?

Let us know how we can help you get started with advanced run time monitoring and predictive maintenance solutions. Learn more at: Co-pilot.cornellpump.com

#CornellCoPIlot #TuesdayTip #RPM2 #PumpRunTime #MaintenanceMadeEasy #CornellPump #DataDrivenMaintenance #RentalEquipmentCare