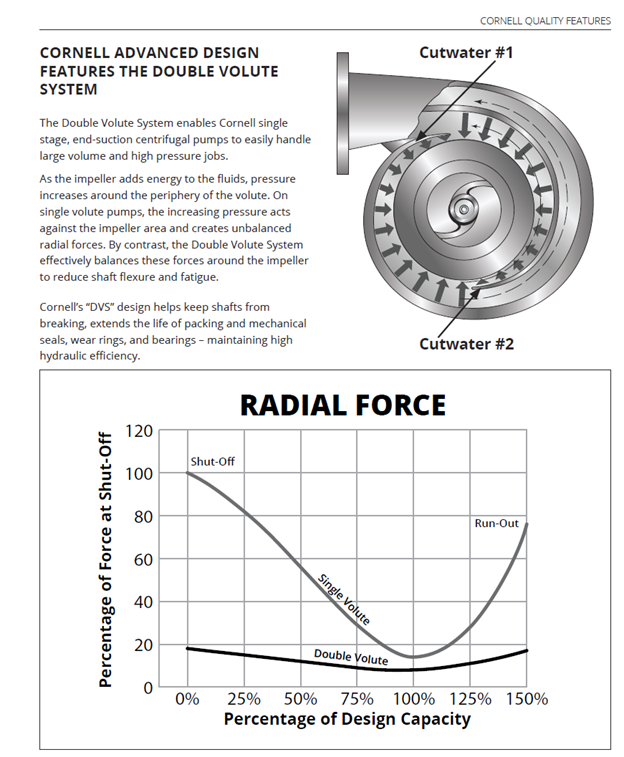

Balanced Radial Loads

A single volute design channels all the fluid into one discharge path. This creates uneven pressure distribution around the impeller, leading to unbalanced radial forces that push against the shaft and bearings. A double volute, by contrast, splits the flow into two equal, opposing passages. The result is a much more balanced hydraulic load, reducing shaft deflection and extending the life of seals, bearings, and sleeves.

Improved Reliability & Longer Component Life

Because radial loads are balanced, components experience less wear and tear. This translates into:

- Extended bearing life

- Reduced shaft bending (lower risk of mechanical seal failures)

- Fewer unplanned outages and less downtime

Higher Efficiency Across the Curve

Double volute designs often maintain efficiency over a broader operating range. By reducing hydraulic imbalances, the pump can handle flows off the Best Efficiency Point (BEP) more smoothly. That means greater flexibility in real-world operating conditions without sacrificing longevity.

Cost Savings Over Time

While a double volute design may add some initial cost, the payoff comes in reduced maintenance expenses, longer mean time between repairs (MTBR), and lower lifecycle costs. For end users, that often makes it the smarter long-term choice—especially in high-duty applications like municipal, industrial, and mining pumping.

Tip Recap: Double volutes balance hydraulic forces, extend pump life, improve efficiency across a wider range, and save money in the long run.

Test can image from Cornell’s Hydraulic Seminar Workbook, covering Double Volutes