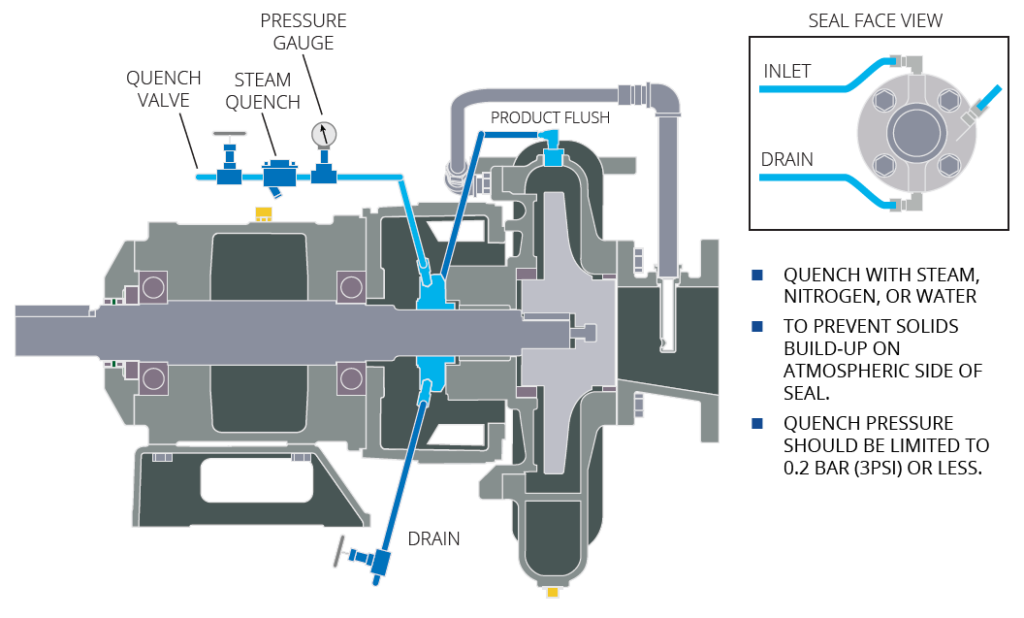

The steam quench prevents the formation of solidified residues—such as coked oil—on the atmospheric side of the mechanical seal. These buildups can lead to premature seal failure and unplanned downtime. By introducing a low-pressure quench (limited to 0.2 bar or 3 PSI), operators can keep this critical area clean and free of obstructions, significantly extending seal life and supporting consistent pump performance.

This steam quench option offers several important advantages:

- Operational Safety: Reduces risk of leakage and potential equipment damage by maintaining a clean seal interface.

- Reduced Downtime: Protects against product buildup that can cause seal degradation and equipment stoppage.

- Extended Seal Life: Maintains a stable environment around the seal faces, enhancing performance in demanding applications.

- Ease of Maintenance: The cartridge seal design simplifies installation and repair, and lowers the likelihood of shaft galling.

The cartridge seal with steam quench is part of Cornell’s commitment to innovation in high-temperature pumping systems. Combined with advanced features like dry-run tolerance, robust construction, and proven hot oil performance, this seal configuration helps ensure long-term reliability for demanding operations.

For more information, see the flyer.