Engineered for Demanding Industrial Applications

Industrial operations—from manufacturing plants to chemical processing facilities—demand equipment that can move challenging fluids with minimal downtime and maximum efficiency. Cornell’s N Series pumps are designed to deliver exactly that.

Key benefits for industrial users include:

- Efficiencies up to 82 %, helping to lower total operating costs.

- Flows up to 36,000 GPM, making them suitable for large-volume process streams.

- Solids-handling capabilities up to 5.3 inches, ideal for process water, slurry, and waste streams.

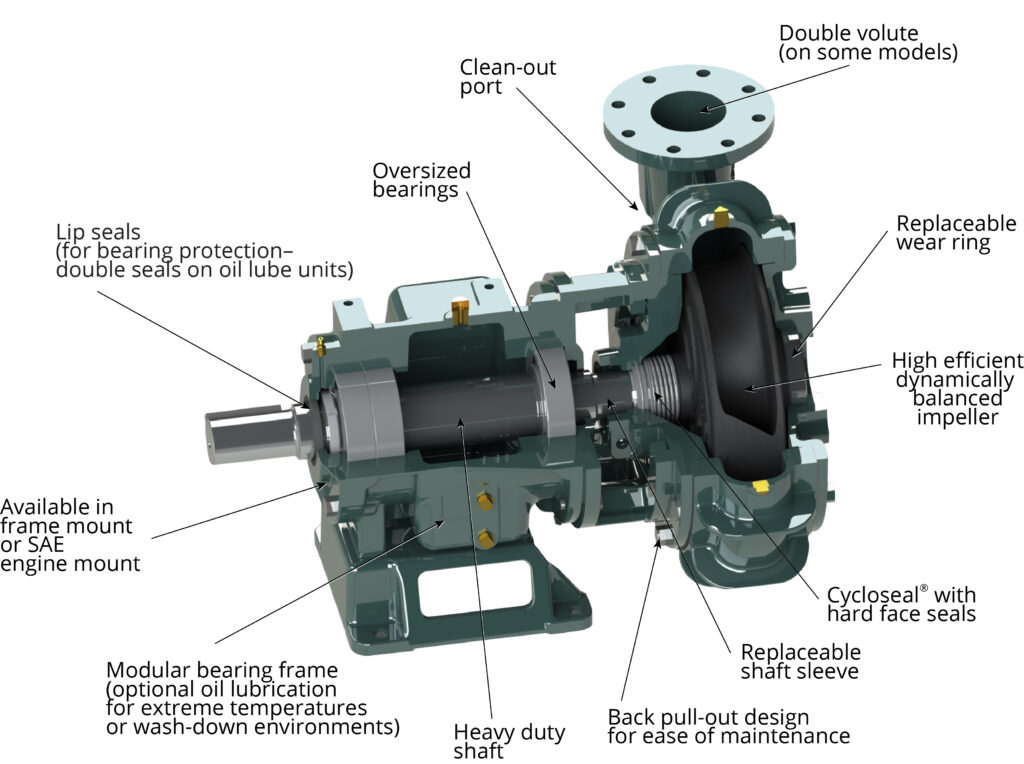

- Heavy-duty construction, including thick casting walls, oversized shafts, and dynamically balanced impellers for long service life.

- Back pull-out design, enabling quick maintenance without disturbing system piping.

- Dynamically balanced impellers for optimal hydraulic efficiency

- Oversized bearings with minimum 20,000-hour life for long service intervals

- Replaceable wear rings and shaft sleeves to simplify maintenance

- Heavy-walled castings and low shaft deflection to extend pump life

- High suction lift capabilities for difficult priming conditions

- Double volute designs to reduce radial load and shaft deflection

These features help industrial operators maintain production uptime while reducing lifecycle costs and unplanned outages.

Proven in Mining, Rental, and Municipal Settings

While the N Series is a natural fit in industrial settings, its versatility and durability have made it equally valuable in other demanding environments:

Mining

- Handles abrasive slurries and tailings with optional CD4MCu duplex stainless-steel construction.

- Available with chopper or cutter impellers to break down stringy or fibrous solids.

- Robust design withstands the high-pressure, high-wear conditions of mine dewatering and processing operations.

Rental

- Offered in multiple configurations—including SAE engine mount, close-coupled, horizontal, and vertical—to suit temporary installations.

- Compatible with Cornell’s Redi-Prime® and Run-Dry™ systems, enhancing performance in variable-flow and intermittent-use scenarios common in rental applications.

- Reliable performance minimizes service calls and increases rental fleet ROI.

Municipal

- Well-suited for wastewater lift stations, stormwater transfer, and sludge handling.

- Double-volute designs reduce radial loading, extending bearing and seal life.

- Cornell’s patented Cycloseal® system keeps grit and solids away from seal faces, eliminating the need for external seal flush water.

These attributes help municipalities and utilities reduce maintenance costs and extend asset life while protecting public infrastructure investments.

Configurations and Customization

Cornell offers the N Series in discharge sizes from 3 inches to 24 inches, with an extensive selection of mounting options and materials of construction. The product line also includes:

- Delta-style impellers for stringy materials.

- Enclosed impellers for spherical solids.

- Semi-open slurry impellers for high-head, soft-solid applications.

- Waste Warrior cutters and blade cutters for clog-prone installations.

With dozens of standard models—and the ability to engineer custom configurations—Cornell can match an N Series pump to almost any system requirement.

Patented Sealing Technology

At the heart of Cornell’s competitive advantage is its patented Cycloseal® system. Unlike standard mechanical seals, Cycloseal® uses cast-in deflector vanes and a dished backplate to actively remove solids, grit, and entrained vapor from the seal chamber—without requiring external flush water. Benefits include:

- No flush water required

- Three-times longer seal life than standard seals

- Reduced maintenance and downtime

- Cleaner, drier installation environment

For applications where dry operation is possible, the optional Run-Dry™ system lubricates and cools the seal faces during priming, re-priming, or standby, preventing seal failure in low-flow conditions.

Impeller Options for Every Challenge

N Series pumps are offered with a variety of impeller styles to match the material being pumped:

- Enclosed two-, three-, or four-port impellers for large spherical solids

- Delta impellers to manage straw, rags, and stringy debris

- Semi-open slurry impellers for soft or fibrous solids

- Cutter and chopper assemblies (including Waste Warrior®) to combat clogging in high-debris environments

These configurations make the N Series ideal for wastewater, sludge, industrial waste streams, stormwater, tailings, and other difficult-to-pump materials.

Why Choose Cornell N Series?

- Built in the USA and backed by a two-year warranty.

- Designed for maximum uptime, minimal maintenance, and outstanding hydraulic performance.

- Supported by Cornell’s extensive distributor and service network.

Whether pumping industrial process water, moving abrasive mine slurries, transferring stormwater, or tackling tough municipal solids, the N Series offers unmatched durability and value.