Built for Harsh Conditions

Our pressure transducers are constructed from 304L Stainless Steel, providing excellent resistance to corrosion, weather, and extreme temperatures. This ensures durability and accuracy, even in demanding applications across water, wastewater, industrial, agricultural, mining, municipal and rental pumping systems.

Case Study: Eliminating Cavitation-Related Downtime

The Challenge

A manufacturing plant was experiencing frequent pump failures and process interruptions caused by:

- Undetected suction cavitation

- Blocked discharge lines leading to overpressure

- No real-time visibility into pump performance

These issues resulted in unscheduled downtime, high maintenance costs, and delayed production schedules.

The Solution

By installing Cornell Pump’s Co-Pilot™ system with suction and discharge pressure transducers, the facility gained:

- Immediate alerts via email, text, or phone when pressures exceeded preset thresholds

- Remote shutdown capability through Co-Pilot™ and Modbus (when integrated)

- Continuous real-time data and customizable reports for operational analysis

The result:

- Faster response to potential issues

- Reduced equipment stress and maintenance costs

- Increased operational uptime and reliability

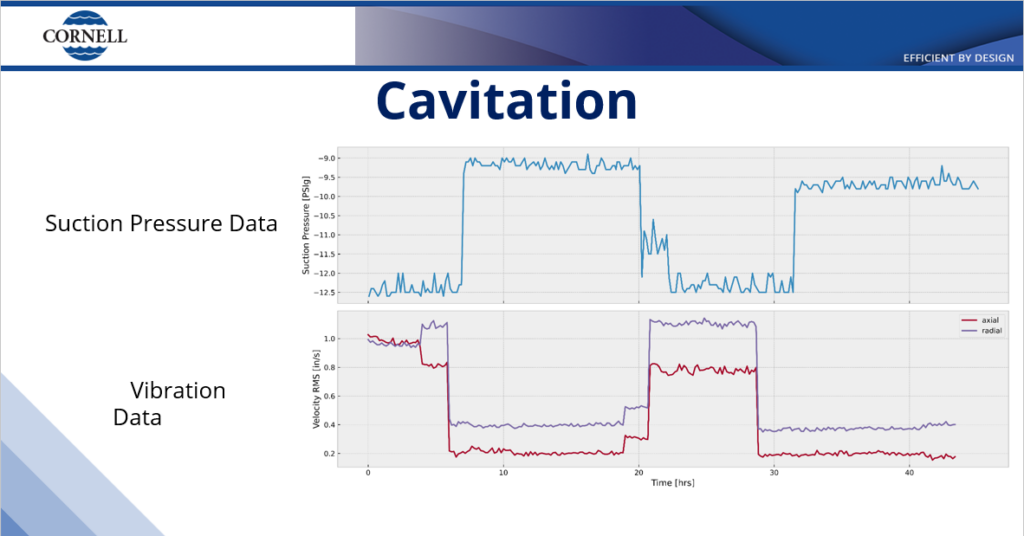

Cavitation Insights in Action

The graph below shows suction pressure (top) and vibration data (bottom) over time. When suction pressure dropped into the cavitation range, vibration readings spiked, signaling potential damage to pump components. With pressure transducers in place, such events trigger automatic alerts, allowing operators to take corrective action before failure occurs.

Smarter Pump Management Starts Here

Pressure transducers—when paired with Co-Pilot™—enable predictive maintenance, optimize pump run times, and help protect your investment. Whether your goal is reducing unplanned outages, improving safety, or extending pump life, Cornell Pump’s integrated monitoring solutions give you the tools you need to operate efficiently and confidently.

Visit https://www.cornellpump.com/co-pilot/ to learn how pressure transducers can improve your system’s performance and reliability.