Why NSF 61 Certified Pumps are Essential for Potable Water

Access to safe drinking water is a fundamental public health priority—and ensuring that water stays clean and uncontaminated as it moves through distribution systems is a critical part of that mission. That’s where NSF 61 certified pumps come in.

Leveraging Rental Cutter Pumps for Emergency Bypass Success

Robust, Reliable Solutions When Infrastructure Challenges Strike

Celebrating National Forklift Safety Day!

At Cornell Pump, forklifts play a vital role in our daily operations at all three of our locations. These hardworking machines lift and move pumps weighing up to 5,000 lbs—and sometimes even more.

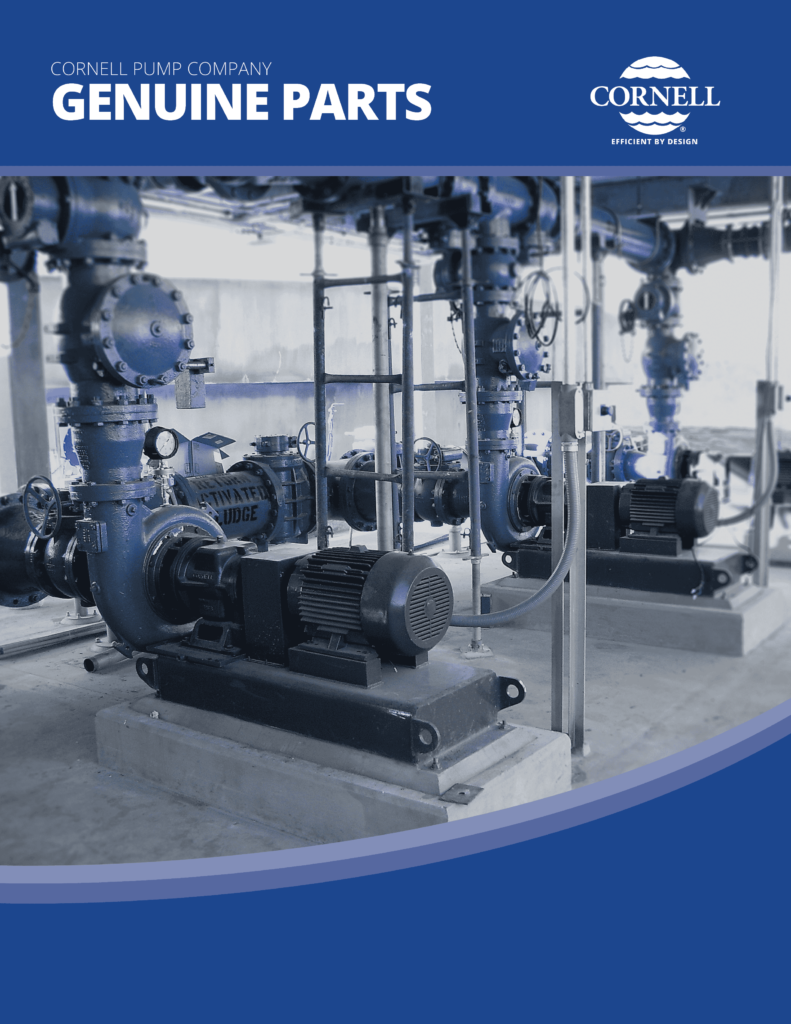

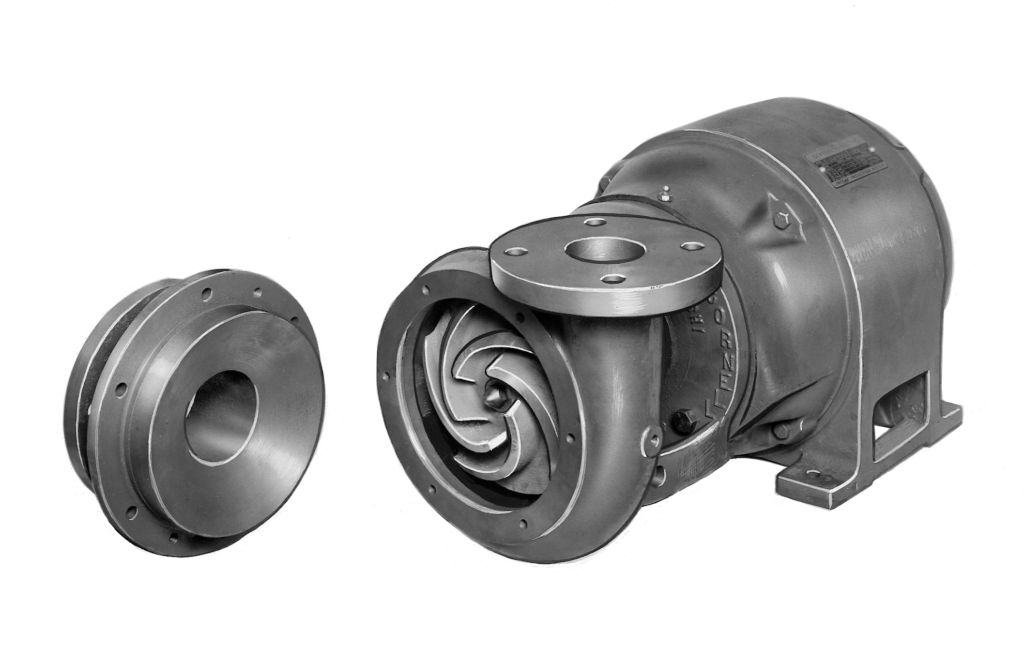

Why Using Genuine Cornell Parts Matters

When it comes to pumps, quality and reliability aren’t just nice-to-haves—they’re mission-critical. That’s why using genuine Cornell parts isn’t just a suggestion—it’s an investment in your system’s performance, safety, and longevity.

The Power of Mobile Flow Meters: Accurate, Convenient, and Essential

Flow meters are crucial tools in many pumping applications —ensuring precise measurement of liquid flow, tracking usage, and supporting critical data collection. Mobile flow meters bring these capabilities to the next level, offering easy deployment and monitoring in remote or challenging environments.

Why Energy Efficiency is So Important with Pump Operation—A World Environment Day Reminder

World Environment Day, observed each year on June 5th, is a global call to action for sustainability and environmental protection. It’s a timely reminder that every choice we make—large or small—impacts our planet. One of the most significant ways to support this mission is by focusing on energy efficiency in industrial operations and pump operational efficiency is a critical component.

The first Cornell agricultural pump was introduced in 1949. Today, we offer more than 110 models for agricultural applications!

Cornell’s story began in 1946 when five employees from Pacific Pump Company decided to start their own company. With a fully equipped service department and firsthand experience repairing pump failures—including issues with motor overloading, pressure spikes, and water damage in pump-end motor bearings—they were ready to build something better. Leveraging their comprehensive inventory and manufacturing expertise, they could service any pump.

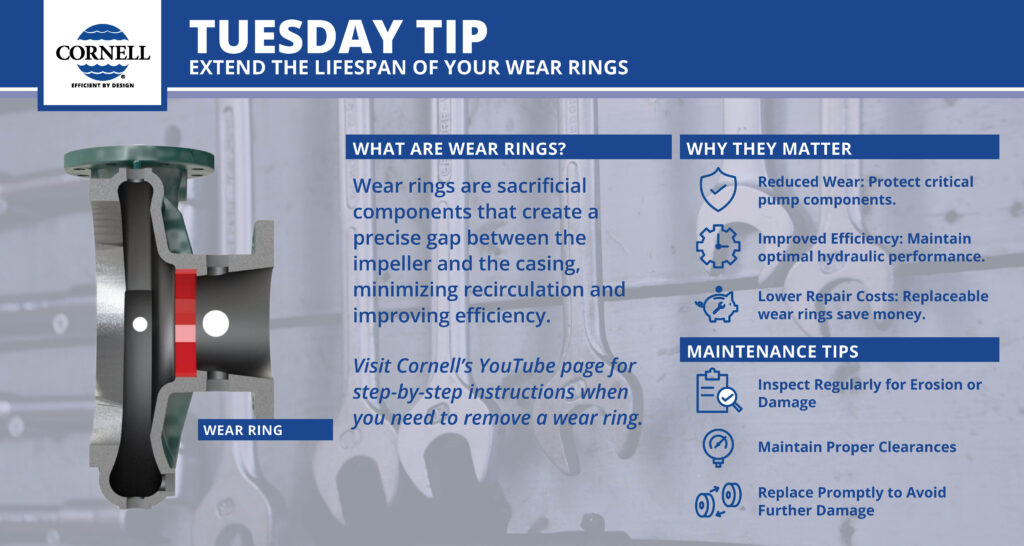

Extend the Lifespan of Your Wear Rings: How This Small Component Makes a Big Impact

Wear rings might seem like small parts in a centrifugal pump, but they play a crucial role in overall performance, efficiency, and maintenance costs. Proper care and maintenance of your pump’s wear rings can dramatically improve efficiency and reduce long-term expenses.

Cornell Pump Will Be Closed for Memorial Day

In honor of Memorial Day, Cornell Pump will be closed on Monday, May 26, 2025. We will reopen at 7:00 AM PDT on Tuesday, May 27.

We take this time to salute and remember the brave men and women who gave the ultimate sacrifice in service to our country.

Registration open — attend Cornell’s 2025 Pump School!

Cornell’s 2025 Pump School is set for September in Portland. The event will occur on Tuesday, September 9, and Wednesday, September 10, 2025. It also includes a Monday night reception for those registrants who can attend.