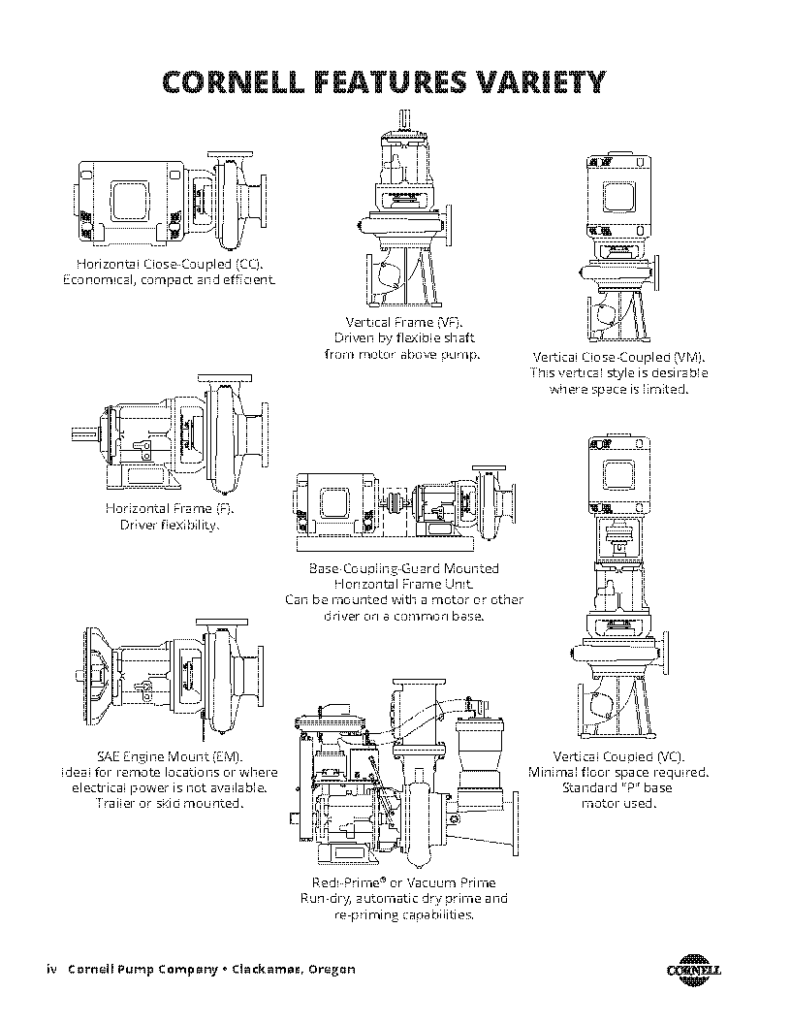

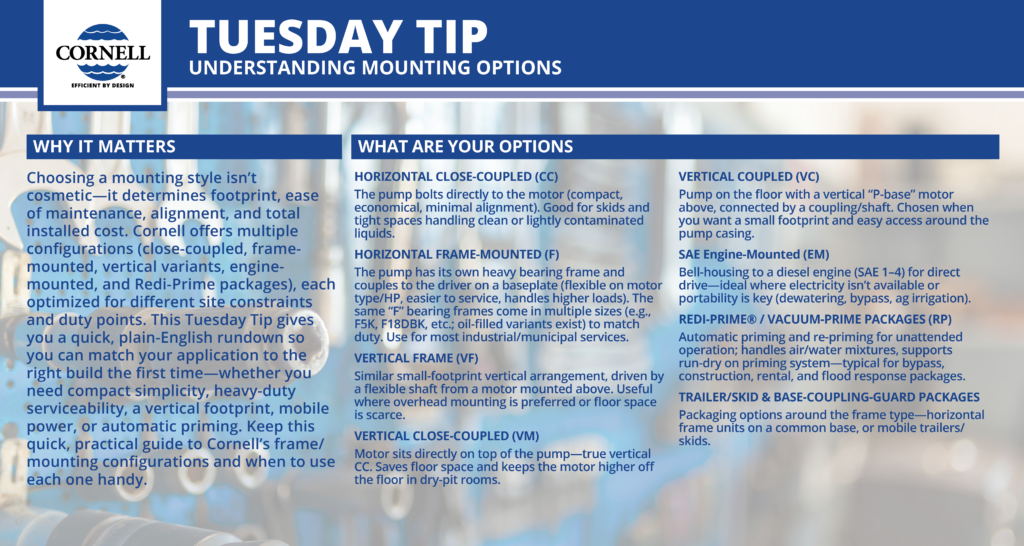

Horizontal Close-Coupled (CC)

The pump bolts directly to the motor (compact, economical, minimal alignment). Good for skids and tight spaces handling clean or lightly contaminated liquids.

- Often for: Clear liquids and applications where footprint and cost are top priorities (e.g., package systems, OEM skids).

Horizontal Frame-Mounted (F)

The pump has its own heavy bearing frame and couples to the driver on a baseplate (flexible on motor type/HP, easier to service, handles higher loads). The same “F” bearing frames come in multiple sizes (e.g., F5K, F18DBK, etc.; oil-filled variants exist) to match duty. Use for most industrial/municipal services.

- Often for: Industrial/municipal duty, higher loads, solids handling, and where maintainability and driver flexibility matter. (Common “F##” sizes, e.g., F5, F16.)

Vertical Frame (VF)

Similar small-footprint vertical arrangement, driven by a flexible shaft from a motor mounted above. Useful where overhead mounting is preferred or floor space is scarce

- Often for: Tight floor space, pits/sumps, or layouts that favor a vertical stack while keeping the heavy-duty bearing frame benefits.

Vertical Close-Coupled (VM)

Motor sits directly on top of the pump—true vertical CC. Saves floor space and keeps the motor higher off the floor in dry-pit rooms.

- Often for: Clear liquids and small footprints where vertical orientation is preferred and alignment simplicity is valuable.

Vertical Coupled (VC)

Pump on the floor with a vertical “P-base” motor above, connected by a coupling/shaft. Chosen when you want a small footprint and easy access around the pump casing

- Often for: Above-grade motor with pump centered over suction; when a vertical footprint and standard motor mounting are desired.

SAE Engine-Mounted (EM)

Bell-housing to a diesel engine (SAE 1–4) for direct drive—ideal where electricity isn’t available or portability is key (dewatering, bypass, ag irrigation).

- Often for: Bypass, dewatering, mining, rental fleets, and any site without reliable power. (You’ll see EM sizes like EM5/EM16.)

Redi-Prime® / Vacuum-Prime Packages (RP)

Automatic priming and re-priming for unattended operation; handles air/water mixtures, supports run-dry on priming system—typical for bypass, construction, rental, and flood response packages.

- Often for: Unattended operation on bypass and dewatering where suction lift/priming is required.

Trailer/Skid & Base-Coupling-Guard Packages

Packaging options around the frame type—horizontal frame units on a common base, or mobile trailers/skids.

- Often for: Rapid deployment, rental fleets, or turnkey plant installs.

How to read Cornell suffixes (what you’ll see on data sheets)

- -CC = Close-Coupled

- -F = Horizontal Frame-Mounted

- -VF = Vertical Frame-Mounted

- -VM = Vertical Close-Coupled

- -VC = Vertical Coupled (P-base motor)

- -EM = SAE Engine-Mounted

- -K= oil lubricated

- Grease= no letters denoting grease added to frame description; assumed unless K designated

- -RP- prefix/suffix = Redi-Prime package (e.g., RP-F, RP-EM)

Example: the 4NNT sheet lists CC, VM, F, VF, EM, VC as available mountings and calls out specific frame sizes like F16 and VC16.

Quick selection cheat sheet

- Tight mechanical rooms / OEM skids, clean liquids: Horizontal CC.

- General industrial & municipal duty, higher loads, easier maintenance access: Horizontal Frame-Mounted (F).

- Dry-pit wastewater rooms with limited floor space: VM or VC vertical arrangements.

- Remote sites / portable sets (dewatering, bypass, irrigation): SAE Engine-Mount (EM), often with Redi-Prime®.

- Flood-prone areas or where you want motors elevated: VM/VC/VF to lift the motor above splash/flood level.

- Need auto-priming or frequent start/stop with air in the line: add Redi-Prime® to the chosen frame

Notes on bearing frames

Cornell offers multiple bearing-frame sizes and both grease- and oil-filled versions; oil-filled frames use lip-seal lubrication and have defined oil capacities/renewal intervals (e.g., F5K ~0.5 qt; F18DBK ~2 qts; F20DBK ~11.8 qts, etc.). That lets you match the frame to load, speed, and orientation demands.

Images of common frame styles from Cornell’s Installation and Care Manual