Based on Cornell Pump’s Installation & Care Manual

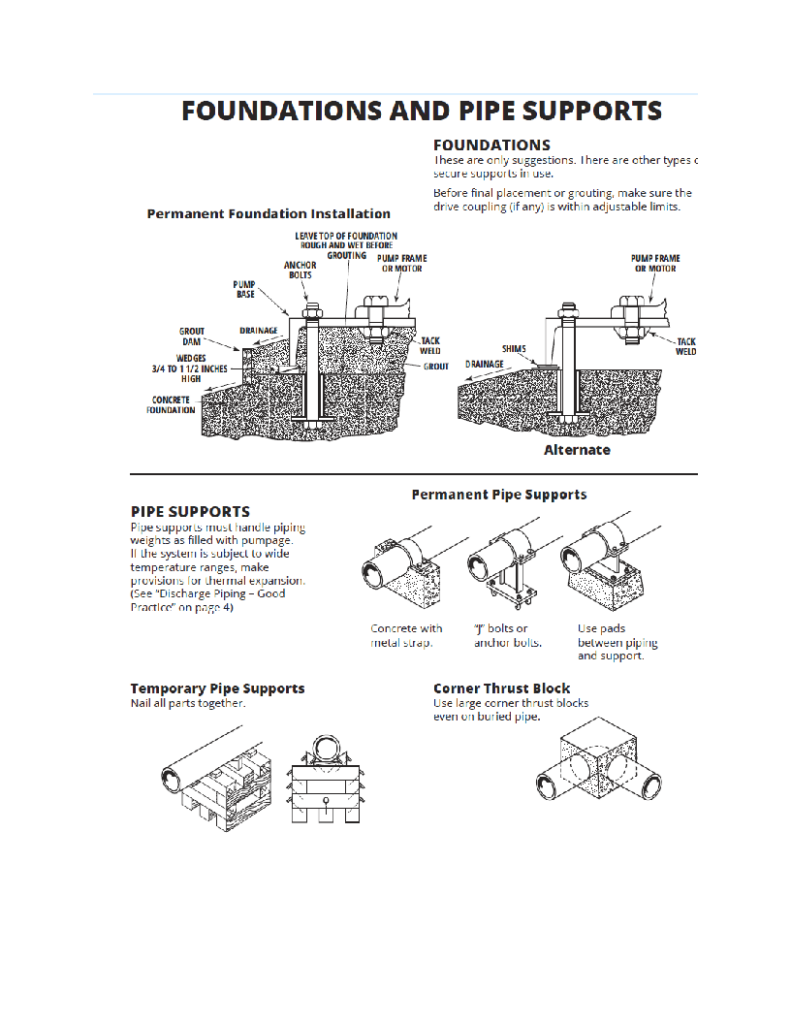

Do: Install a Proper Foundation

- Use a concrete base with wedges or shims for accurate leveling.

- Leave the top of the foundation rough and damp prior to grouting for better adhesion.

- Confirm the pump and motor are aligned before grouting or final bolting.

- Use a grout dam to ensure clean and effective containment.

- A properly installed foundation minimizes vibration, maintains alignment, and contributes to long-term equipment life.

Don’t: Rush or Skip Key Steps

- Do not place pumps directly on uneven surfaces or unsupported pads.

- Never grout or bolt the base before confirming motor-to-pump alignment.

- Do not allow the piping to bear the pump’s weight—this creates mechanical stress that can damage components.

Improper foundation work leads to increased maintenance, poor performance, and possible equipment failure.

Do: Support Piping Correctly

- Ensure all piping supports can handle the full weight of liquid-filled lines.

- Use permanent supports such as concrete blocks, anchor bolts, and metal straps.

- Allow for thermal expansion in systems with temperature variation.

- Use cushioning pads between the pipe and support to absorb vibration and movement.

- Well-supported piping maintains pump alignment and reduces load on bearings and seals.

Don’t: Let Piping Stress the Pump

- Avoid hanging piping from the pump or motor assembly.

- Do not skip temporary bracing during installation—it prevents sagging and misalignment.

- Never bolt misaligned flanges together—this causes stress on pump components.

Unsupported or misaligned piping is a leading cause of vibration, leaks, and premature wear.

Summary

Proper foundation and piping support are critical to the success of any pump installation. Following these best practices can reduce downtime, prevent costly repairs, and maximize the lifespan of your equipment.

Content adapted from page 9 of the Cornell Pump Installation & Care Manual.