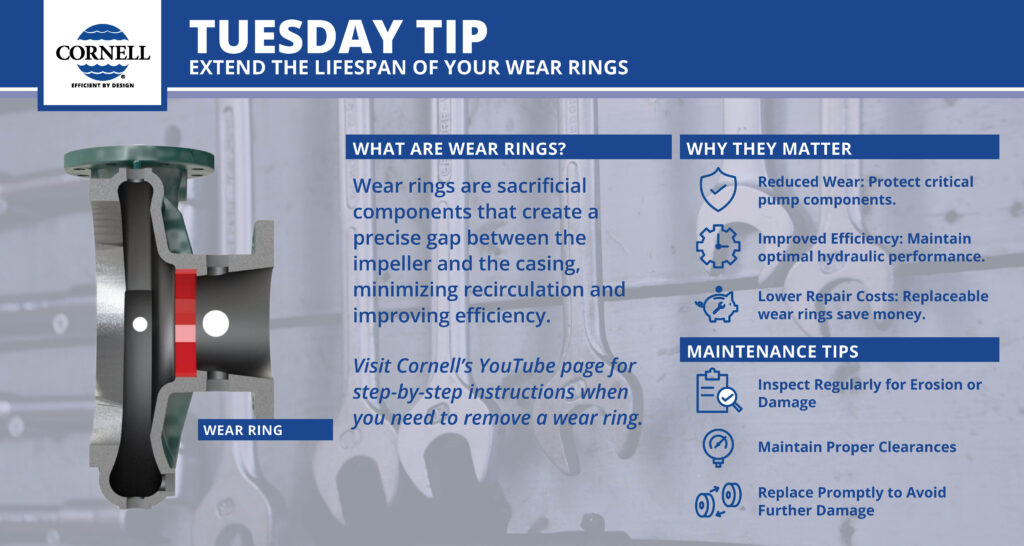

What are Wear Rings?

Wear rings are sacrificial components, typically made of a different material than the impeller or casing. They create a precise gap between the impeller and the casing, which reduces internal recirculation and improves hydraulic efficiency.

Why They Matter:

- Reduced wear: By absorbing abrasion, wear rings help protect critical and more expensive pump components from damage.

- Improved efficiency: Minimizing internal leakage ensures the pump maintains peak performance for longer periods.

- Lower repair costs: Replacing a worn wear ring is far more economical than replacing an entire impeller or casing.

Maintenance Tips:

To keep your pump operating efficiently and avoid costly repairs, follow these guidelines:

- Regularly inspect wear rings for signs of erosion or damage.

- Maintain proper clearances to prevent excessive wear.

- Operate the pump within the recommended duty range.

- Replace worn rings promptly to prevent further damage and preserve efficiency.

By integrating wear ring maintenance into your regular pump care routine, you’ll extend the life of your equipment, minimize downtime, and save money in the long run.

#PumpMaintenance #WearRings #EfficiencyByDesign #CornellPump #PumpCare #Hydraulics