Pumpline Blog

Stay up-to-date with the latest from Cornell.

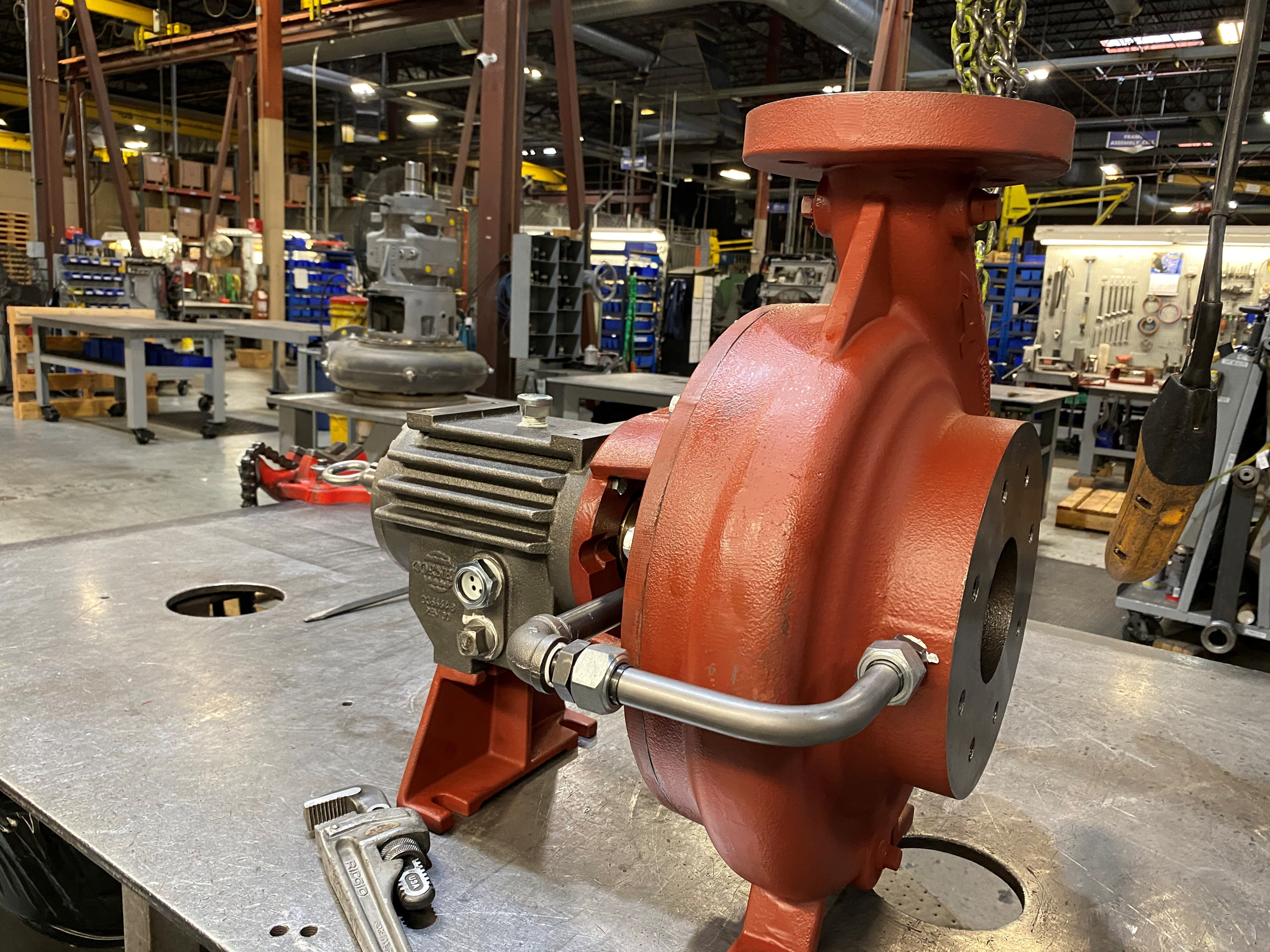

Why is an External Balance Line Important to the Z-Series?

Cornells newest pump, the Z-Series, a line of ANSI-compatible process pumps, features an external balance line. Here is why that innovation makes the Z-Series a better fit for demanding industrial and municipal applications than standard ANSI pumps.

New ANSI Compatible Pumps, the Z-Series!

Cornell Pump is proud to announce our new ANSI compatible process pumps, Z-Series!

Longtime Cornell Pump Employee Retiring After 42 Years

Ted Wiese, Cornell Production Manager, started in 1981.