Food Processing Company swaps out “unreliable, dangerous, and cumbersome,” electrical submersibles for Cornell 6ST.

![]() While displaying Cornell pumps at the Sacramento Food processing show, The Cornell distributor for Central California was approached by the maintenance team from a well-known tomato processing facility in Stockton, California. This plant processes thousands of tons of tomatoes during the harvesting season and very rapidly turns them into various table favorites.

While displaying Cornell pumps at the Sacramento Food processing show, The Cornell distributor for Central California was approached by the maintenance team from a well-known tomato processing facility in Stockton, California. This plant processes thousands of tons of tomatoes during the harvesting season and very rapidly turns them into various table favorites.

As part of the wash segment of processing the delicate fruit, a lot of waste is removed and washed away in what is known as a ‘trash wash.’ This waste has to be moved away from the now clean tomatoes and processed. The trash wash contain not only dirt, but also pieces of stems, bad peels, leaves, and so forth gleaned from good tomatoes, along with rotten or bruised fruit.

Because of the ripening time of tomatoes, the processing plant runs at capacity around the clock for approximately four months straight. Speed is needed to keep premium freshness at a maximum and waste at a minimum. The processing company had been employing large electric submersibles to clean out the giant wash trays in the trash wash section of the plant. They electrical submersibles were not performing well, even being described by the plant personnel as “Unreliable, dangerous and cumbersome.”

One of the main complaints was the inability to monitor the electrical submersibles while they were operational. If the pumps weren’t working efficiently, that wasn’t noticed until the trash wash backed up; delays there impeded the line and imperiled the maximum amount of tomatoes being processed. Ultimately those slowdowns made the plant less profitable than it could have been.

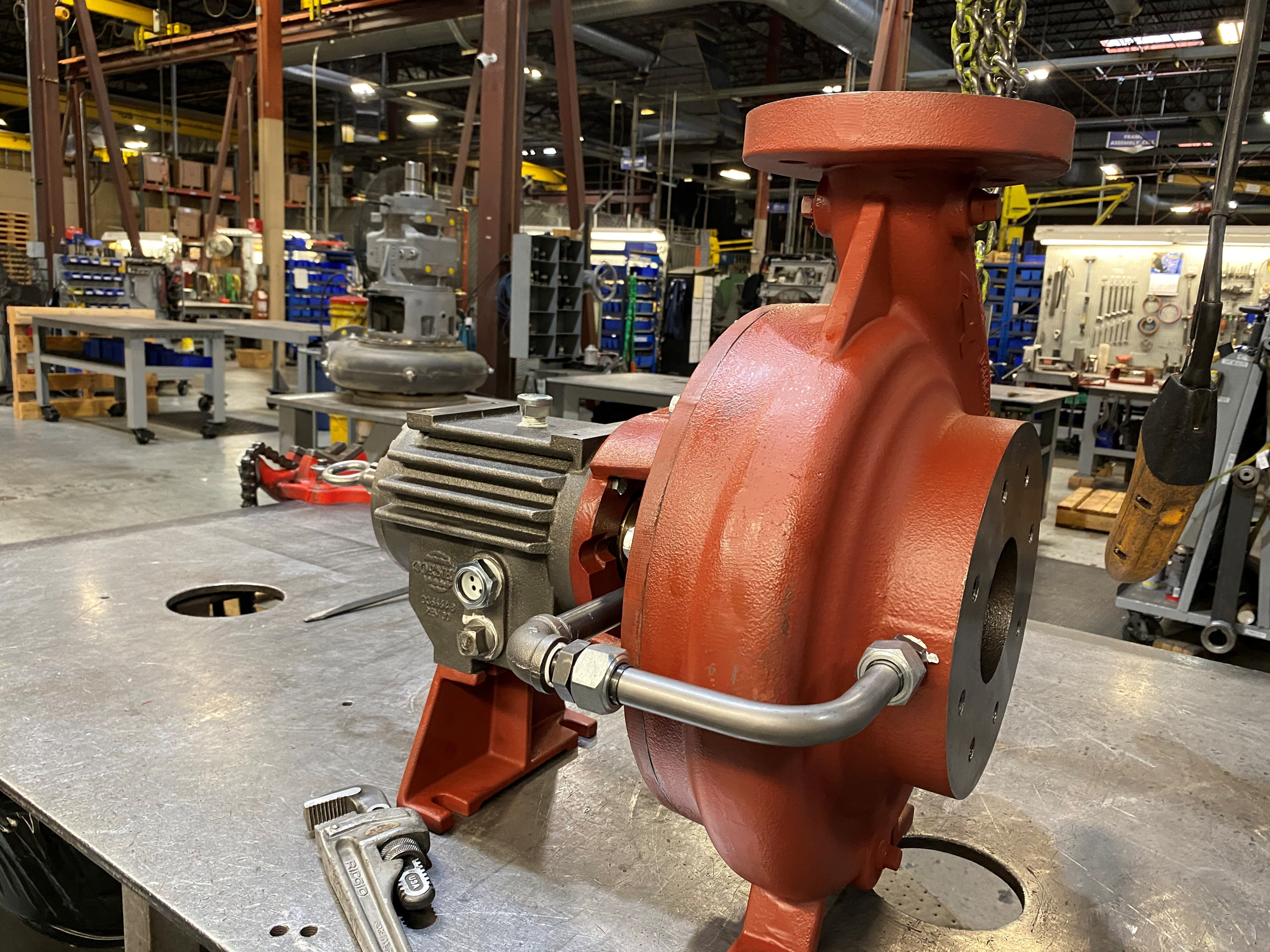

The distributor suggested a self-priming solution from Cornell. With these high quality self-priming pumps, the plant staff can maintain and clean their pumps safely and efficiently. They can tell if there is an issue immediately, and they have the confidence that issues are rare with Cornell. This has helped increase plant efficiency several percent—with millions of pounds of tomatoes that extra efficiency translates into more operating revenue for the plant.

The plant is so impressed with the pumps that they are working with Cornell and the distributor to find other pumps to replace with Cornell’s solids handling, high volume, and high head solutions.