Secret To The Success — Cycloseal® And Efficiency

Secret To The Success — Cycloseal® And Efficiency

Cornell has been active in the agricultural and municipal markets throughout Colombia, South America for a couple decades. Working to convince mining companies of the ultimate price savings of installing premium products with lower operational and maintenance costs has been challenging, however. In 2011, Cornell’s Colombian distributor was able to secure the bid for a dewatering application in the nickel mine located in the Northern Andean region of Colombia. Much work went into securing the contract, as the mine was generally closed to new products, there was an entrenched sales network, and there were concerns about the initial pricing of Cornell relative to lower cost/lower quality competitors.

Despite these challenges, the distributor secured a job for three Cornell 8NHTA-RP-EM18-3 units and provided the engine and pontoon locally to keep the packaged price to a minimum. Three years later, the pumps have been running flawlessly for over 4,500 hours. Not a single spare part has been required, which prevents any additional costs and more importantly, allows the mine to operate without any down time, avoiding any disruption of nickel production.

The dewatering application in the nickel mine is not unique. Cornell has had great success in mines throughout Australia and Indonesia for years. Currently, there are more than 600 units in the Pacific Rim region that are all working as well as in Columbia.

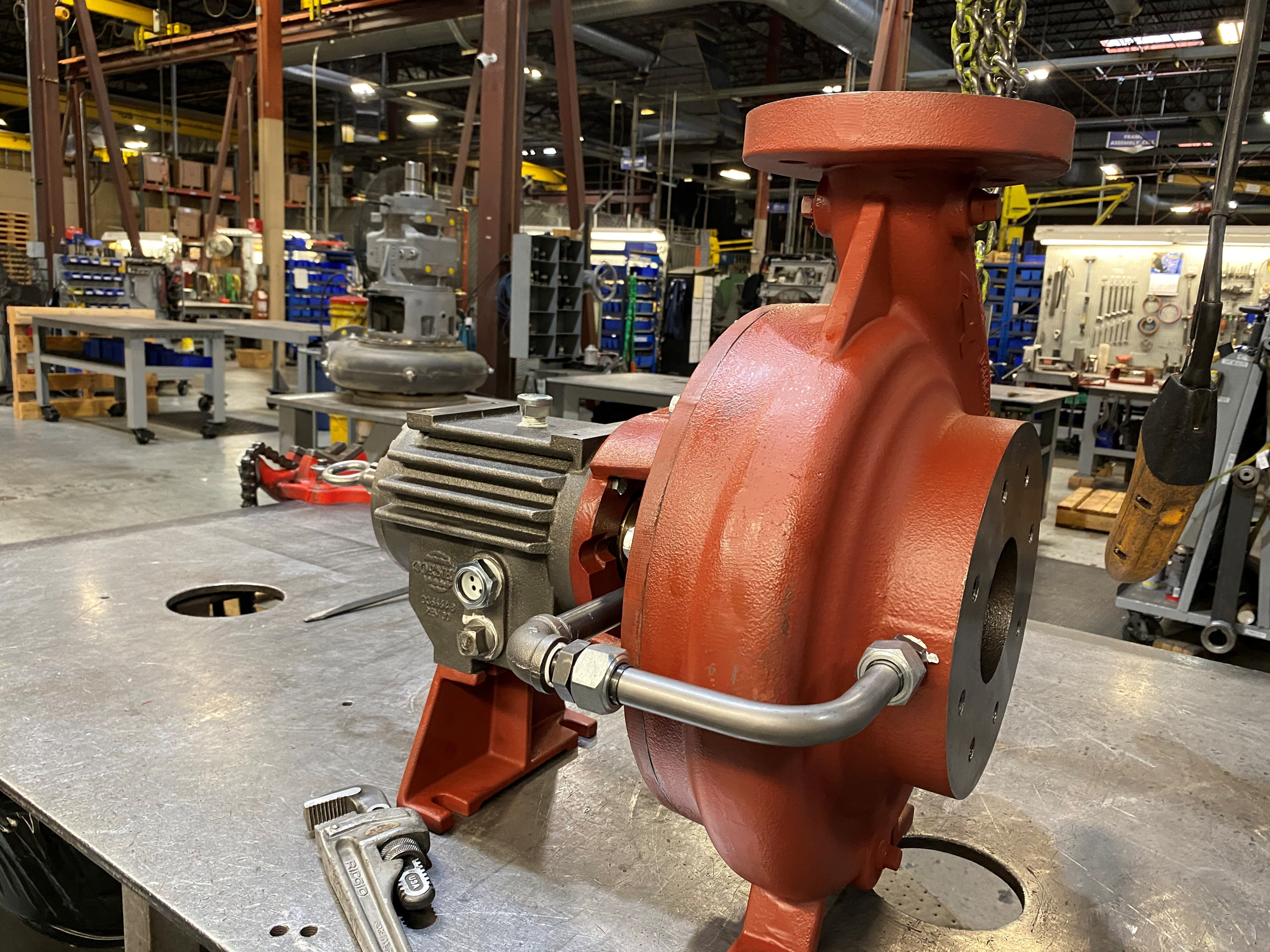

Much of the success is attributable to Cornell’s patented Cycloseal system design which generally reduced seal maintenance at least three fold. Cornell’s Australian distributor hails the Cycloseal design as a game changer for the mines. A typical dewatering application, using a Cornell product, experiences over 15,000 hours of operation before any seal maintenance is required. This is unprecedented with diesel driven applications in such severe environments like mines. More challenging applications, containing 3-5% silt suspended in the water, are still realizing over 5,000 hours before the seal needs replacement or repair.

At an average cost of $5,000 per seal replacement (including drive time, crane rental, labor and seal price), any additional operational time is a huge windfall for the mines. With the Cornell Cycloseal out-performing the competitors, the seal replacement costs become very significant and can justify any initial price difference that may be associated with a Cornell.

Cornell also generally offers industry-leading pump efficiencies. Not only will a customer get the most robust and maintenance-free pump available for the mining market with the purchase of a Cornell, but they will also experience a pump that has the lowest operating costs of any pump available.